Digitalizing Safety Information into Intelligence

Digitalizing Safety Information into Intelligence

Digital Transformation is the process of converting non-digital or manual information into a digital (i.e. computer-readable) format. For an organization, a phase of digital transformation is a great opportunity for organizations to take a step back and evaluate everything they do, from the basic operations to complex workflows.

<p?

Digital transformation is a time to understand the potential opportunity involved in a technology investment. It’s an ideal time to ask questions, such as ‘Can we change our processes to allow for great efficiencies that potentially allow for better decision making and cost savings.’ A perfect example could be trending data to identify optimum test intervals based on degradation over time. This could provide cost savings in fewer required tests.

Advantages of Digital Transformation

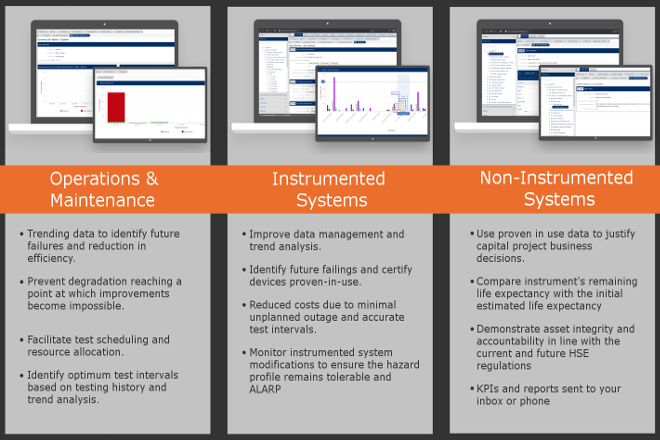

The key tactical benefit of digital transformation is to improve the efficiency of core business processes. In the image below, you can see the efficiencies provided by digital data broken down into three key module areas:

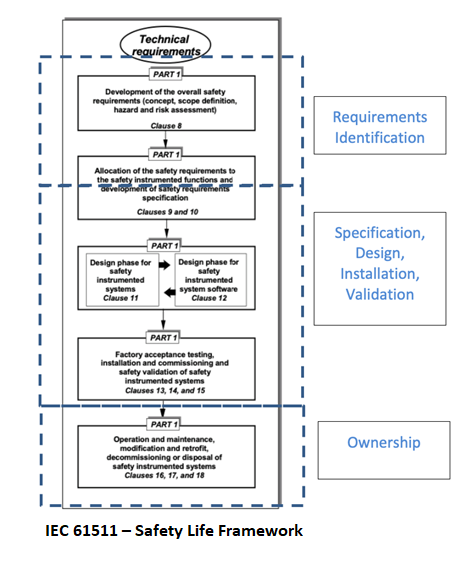

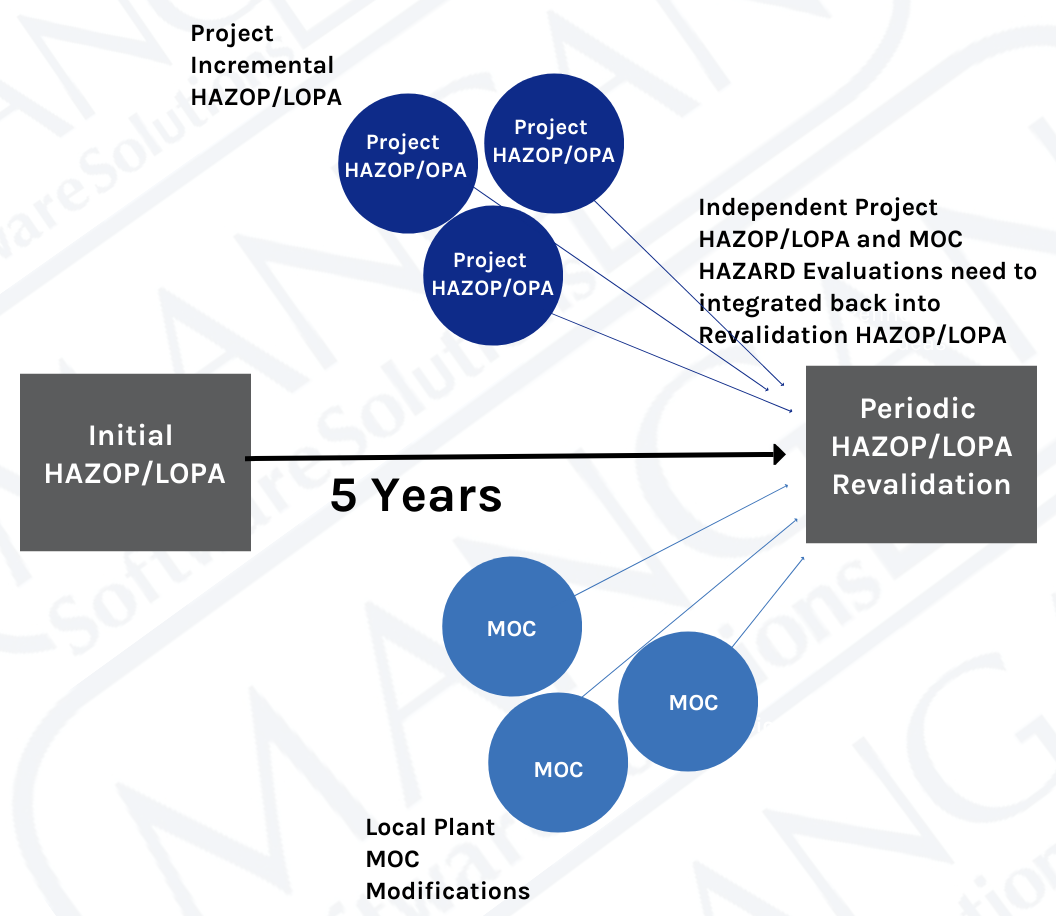

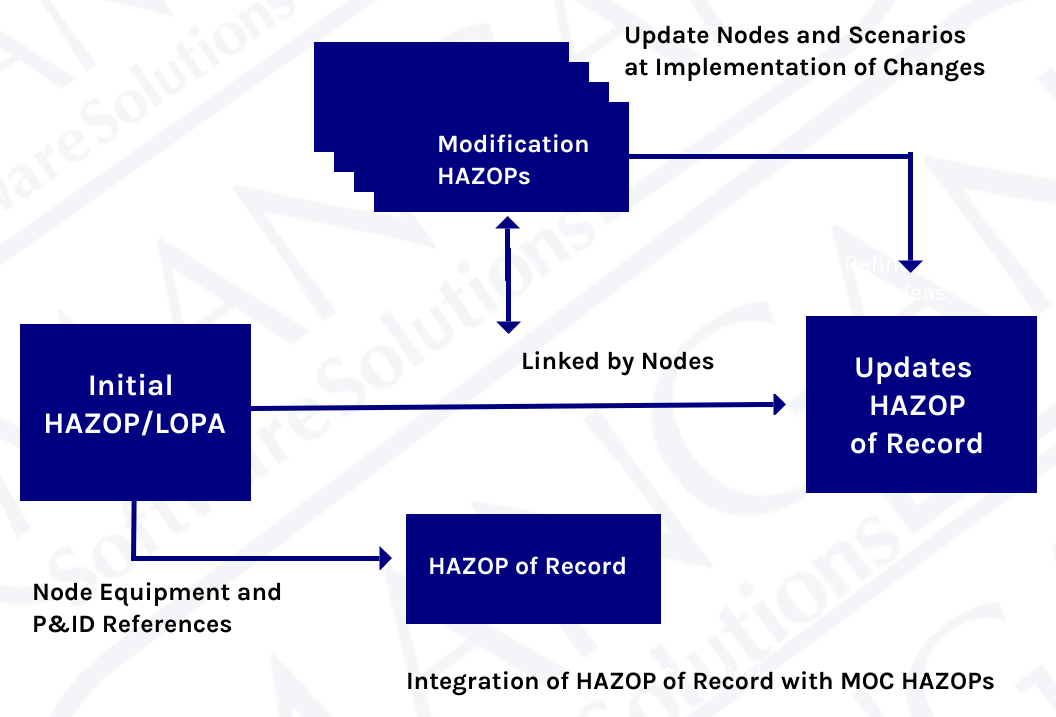

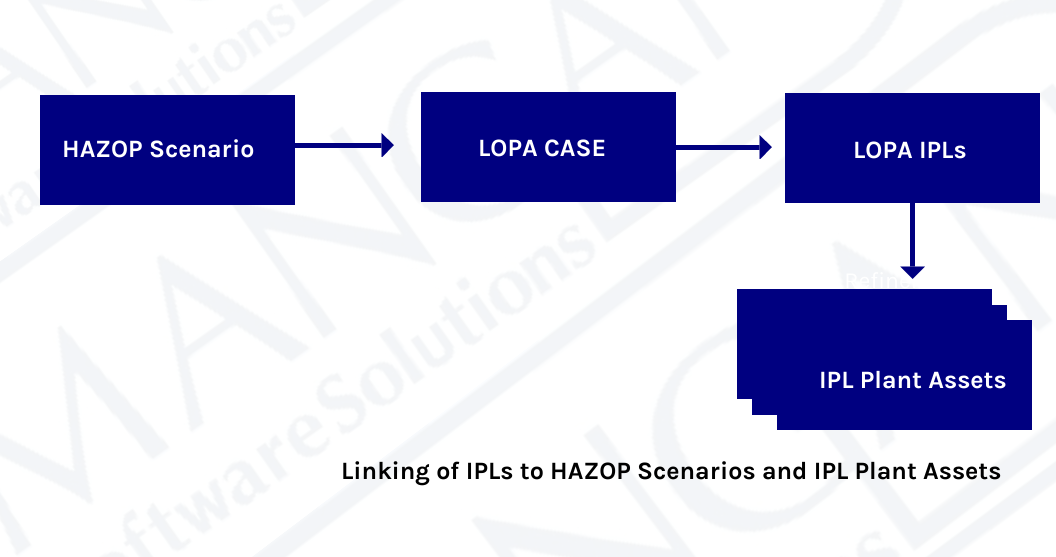

As you can clearly see, the opportunities provided by digitalization are vast and for this reason Digitalization Demands an Integrated Safety Lifecycle Management System A lot of tools in the market today are single purpose and do not share or exchange data in a way suited to a Safety Lifecycle Management system A lot of organizations we speak with are struggling with lagging indicators and poor reporting systems. This degradation has only gotten worse over time, and this points to a lack of clear and accurate data, overly complex workflows and restrictions brought about by company culture. At any given point in time organizations are unable to identify the current health of their plant and assets. Bad actors are exceedingly difficult to identify and experience is diminishing with retirements and a reduction in the numbers of subject matter experts. Process Safety and Functional Safety is more than just hardware, software, testing and metrics. Taking a holistic approach and instilling a culture of safety requires a complete end-to-end system that can manage from Initial Hazard Analysis to the final Operations & Maintenance. The SLM® system is the only enterprise platform proven to bring together all aspects of the Safety Lifecycle through digital transformation. Common problems

Digital Transformation Solution