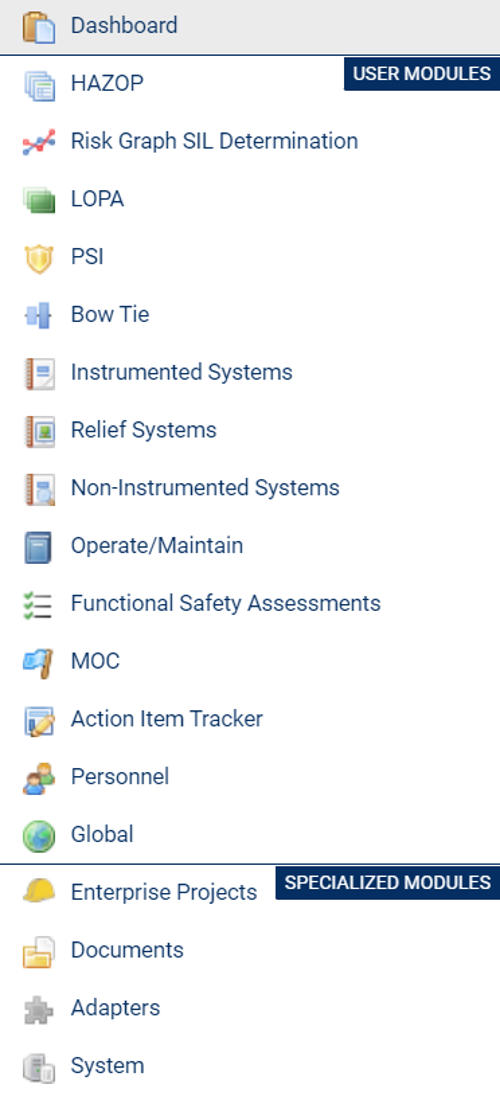

SLM V2 One Platform for the

Complete Safety Lifecycle

SLM V2 is a comprehensive set of interconnected application modules that cover the entire Process Safety and Functional Safety LIfecycle. From HAZOP and LOPA Studies to SIS Design, Operations and Maintenance, SLM V2 has all the tools you need to successfully manage the Safety Lifecycle.

SLM V2 SOFTWARE PLATFORM FEATURES

SLM V2 has software modules for risk assessment and management methodologies like HAZOP, LOPA, and BowTie. As well as Instrumented, Non-Instrumented, and Relief Systems for IPL management and SIS design and SIL verification. To ensure that the designed systems are managed and performance is measured, SLM V2 has an Operate & Maintain, Functional Safety Assessment, MOC, Action Item Tracker, And Personnel Modules to manage the operation and validation of your safety systems and personnel.

All of this inside one Enterprise Ready Software Platform to help you manage the Safety Lifecycle.

SLM V2 SOFTWARE PLATFORM BENEFITS

- Secure Cloud deployment and delivery or On-Premise virtual server instances.

- Designed for user and geographic cloud scaling for multi-site distributed deployments.

- User configurable dashboards for each application module giving users the ability to put what’s important to them up front.

- Modern “Flat” user interface leveraging the latest UI/UX technologies from Telerik, GoJs, and AMCharts.

- Dynamic report filtering, grouping and sorting allowing for deep data inspection in data tables, charts and graphs.

- Export any data object or report to Excel or PDF, to allow for additional manipulation, discussion, dissemination, presentation, and review.

SLM V2 SOFTWARE PLATFORM REQUIREMENTS

SLM-Cloud (SaaS) Requirements

- Current Supported Version of Microsoft Internet Explorer (IE11 or Edge)

- (Or) Current Version of Chrome/Safari/WebKit Browser

On-Premise Installation Requirements

- Microsoft Windows Server 2008 R2/2012

- Microsoft Internet Information Server 7.5/8.5

- Microsoft SQL Server 2012 Standard Edition

- Current Supported Version of Internet Explorer (IE11 or Edge)

SLM V2 Software Modules

The SLM Software Suite is comprised of 12 Software modules that encompass the entire IEC 61511/ISA4 Safety Lifecycle.

Click on a module below for more details.

SLM V2 Atlas™ Platform Modules

The Atlas™ SLM Platform Modules are included as a part of the base system and are used by all of the Software Modules to provide Global Data, Document, Personnel and Configuration Management.

SLM V2 Software Platform Modules

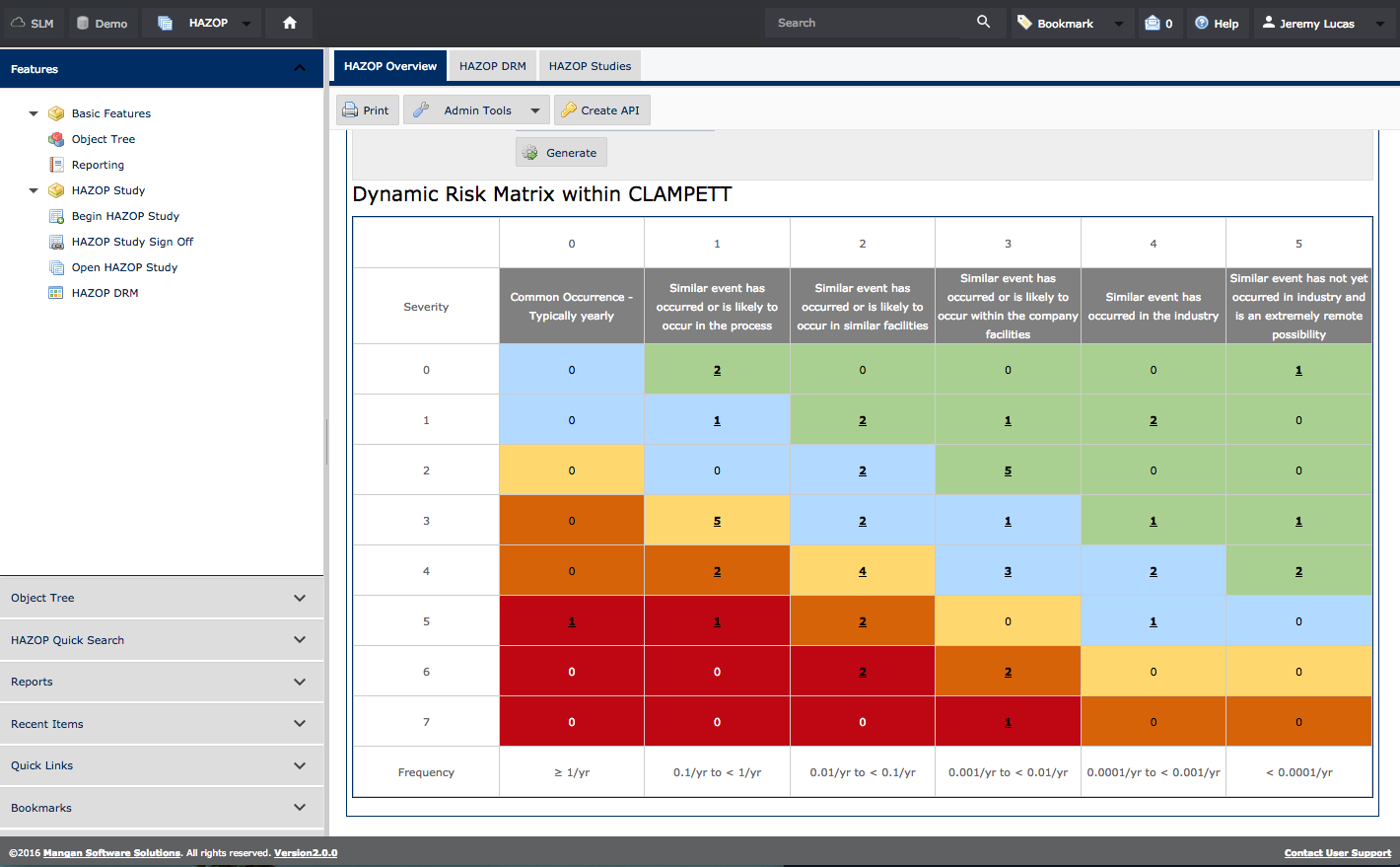

HAZOP

Click on Image to Zoom

- Facilitate HAZOP studies directly in SLM or import HAZOP data from other sources

- Configure HAZOP facilitation tables to company standards and procedures

- Conduct project HAZOPs with option to include the results with the HAZOP of record

- View HAZOP risk assessment results by different levels of scope, such as plant, area, and unit

- Configure and organize user interface tables to fit style preference

- Link process equipment to HAZOP scenarios to determine equipment at risk

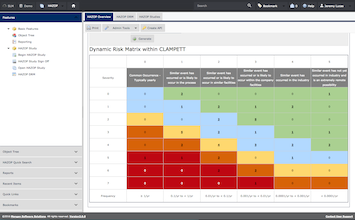

- Plot hazardous scenarios on SLM’s Dynamic Risk Matrix

- Link HAZOP scenarios to LOPA module scenario data

- Link safeguarding barriers with protective systems identified in later Safety Lifecycle modules

- Track HAZOP recommendation gap closures

- Automatically generate Barrier lists as HAZOP scenarios are documented

- HAZOP Facilitation Report that lists all HAZOP Nodes, Deviations, and Scenarios in one complete output to review, email, print, and share with your team or across the organization

- HAZOP Recommendations Report that shows all recommendations from a HAZOP in a simple filterable display to help identify the areas of highest priority for resolution and further study

- Generate Critical Equipment List Report that quickly identifies which equipment is critical to plant safety and how that equipment is covered

- Generate Action Items for further analysis or study by the HAZOP team directly from any recommendations, then assign and track the item it to closure

- Initiate HAZOPs directly from the plant hierarchy at the unit level to quickly start HAZOP studies and drive operational awareness

- HAZOP study approval process with email notification

SLM HAZOP DATA OUTPUTS AND REPORTS

The following Data and Reports are part of the SLM V2 core HAZOP Module.

Managed HAZOP Data :

- HAZOP Studies by Site, and Operational Unit

- HAZOP Study Types (HAZOP of Record, Project, Re-Evaluation)

- HAZOP Dynamic Risk Matrix

- HAZOP Dynamic Risk Report

- Study Properties

- Team Participants

- Sessions

- Nodes

- Study Equipment

- Deviations

- Scenario Causes

- Scenario Consequences

- Scenarios with Suggested Safeguards and Recommendations

- HAZOP Recommendations

- HAZOP Safeguards

- HAZOP Report

- HAZOP Approval Workflow

HAZOP Reports:

- Approved HAZOP Study List Dynamic Risk Matrix

- HAZOP Critical Equipment List

- HAZOP Inherent Risk Chart

- HAZOP Recommendations

- HAZOP Re-Evaluation Timeline

- HAZOP Review

- HAZOP Safeguard List

- HAZOP Scenarios Requiring LOPA vs. LOPAs Performed

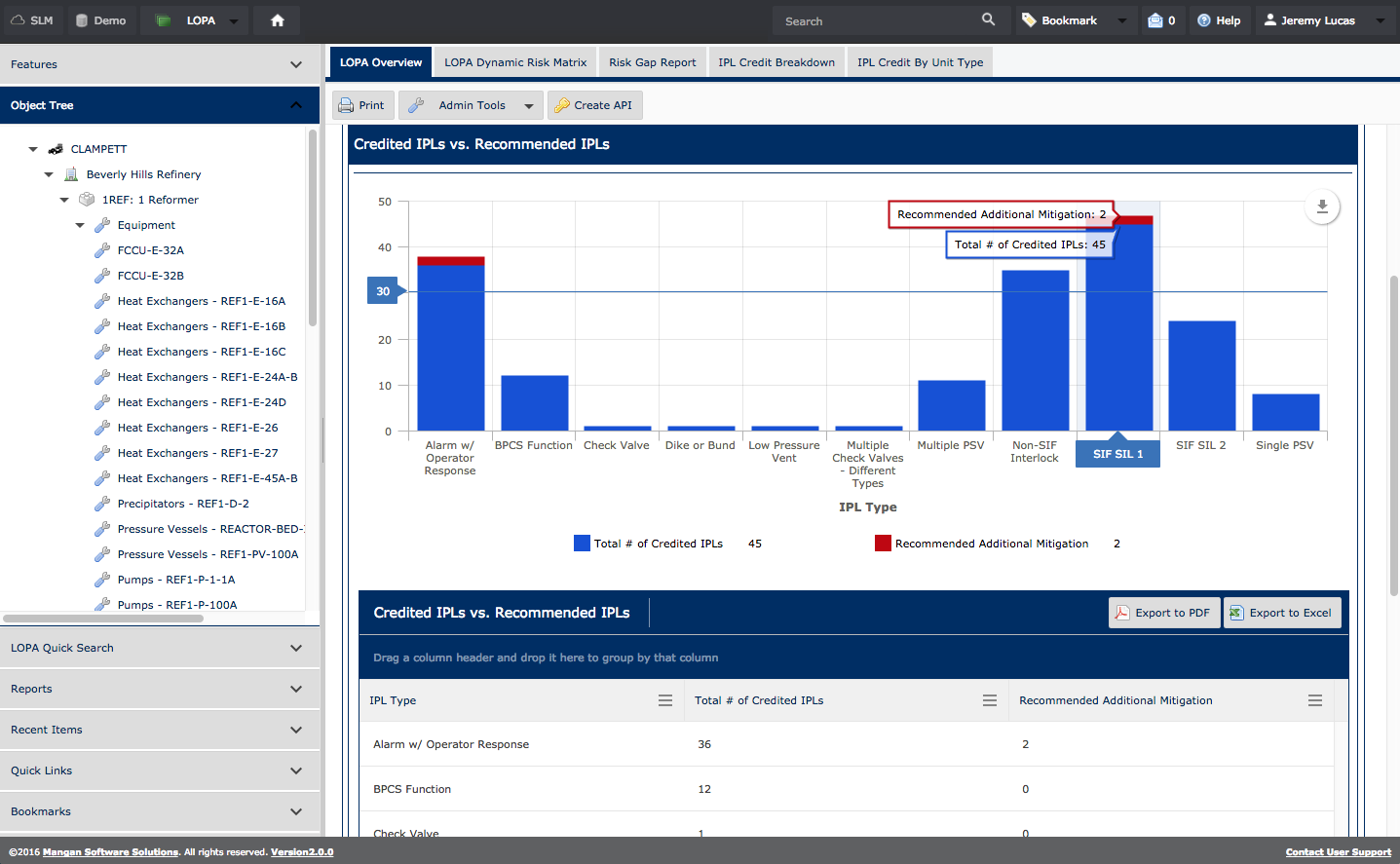

LOPA

Click on Image to Zoom

- Facilitate LOPA studies directly in SLM or import LOPA data from other sources

- Configure LOPA data library tables to company standards and procedures

- Create LOPAs from previously saved LOPA templates

- Link LOPA scenarios with recorded HAZOP module scenarios

- Use same list of barriers as HAZOP module for LOPA scenario mitigation

- Automatically calculate barrier target requirements as LOPA scenarios are documented

- Automatically calculate expected demand rates on barriers

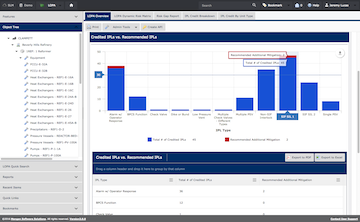

- Combine barrier target requirements across multiple scenarios using the same barrier

- View barrier diagrams displaying sequence of threat propagation through barriers

- Schedule and track scenario and barrier gap closure

- Plot LOPA scenarios on SLM’s Dynamic Risk Matrix showing effect of invalid/inadequate barriers, with option to toggle results to include effects of barriers currently in bypass status

- Link IPL barriers with actual protective systems designed to meet barrier target requirements

- Automatically generate barrier registers from LOPA data

- Track LOPA and barrier recommendations

- Generate Action Items from LOPA recommendations that are automatically added to the Action Item Tracker to ensure all recommendations are mitigated and addressed in a timely manner.

- Generate Critical Equipment List to provide a list of “equipment at risk” identified during a LOPA Study along with the highest risk in each of the equipment's associated LOPA Sheets.

- Filter reports of LOPA scenarios to find specific scenarios containing specific barriers, types of barriers, equipment, and level of severities

- Generate LOPA Recommendations Report to review all recommendations documented within a LOPA Study

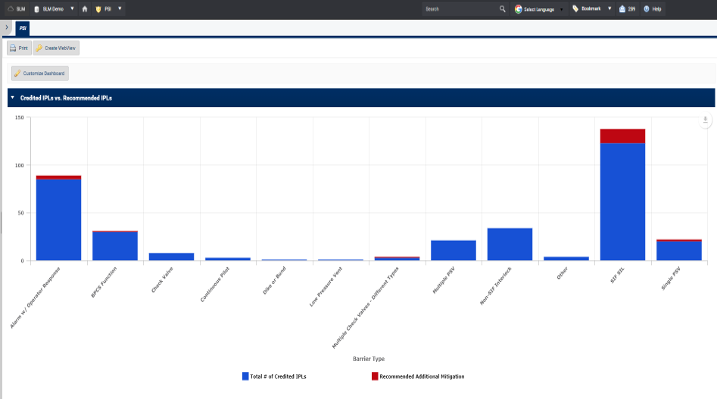

SLM LOPA DATA OUTPUTS AND REPORTS

The following Data and Reports are part of the SLM V2 core LOPA Module.

Managed LOPA Data:

- LOPA Dynamic Risk Matrix

- Risk Gap Report Planed Risk Reduction by Year

- LOPA Equipment Listing

- IPL Register (Enterprise, Site and Unit)

- Credited IPL Register (Site, Unit)

- LOPA Recommendations (Site, Unit)

- LOPA Studies

- LOPA Worksheets

- PHA Consequences and Risk Target

- Frequency Modifiers

- Initiating Causes (IC) x Frequency Modifiers

- Independent Protection Layers (IPLs)

- Probability of Failure on Demand (PFD) of SIF

- Potential Risk Reduction Measures

- Remaining Risk Reduction Factor (RRF) with Recommendations

- Notes, Comments, Calculations

- IPL Study Tasklists

- LOPA Recommendations and Action Items

LOPA Reports:

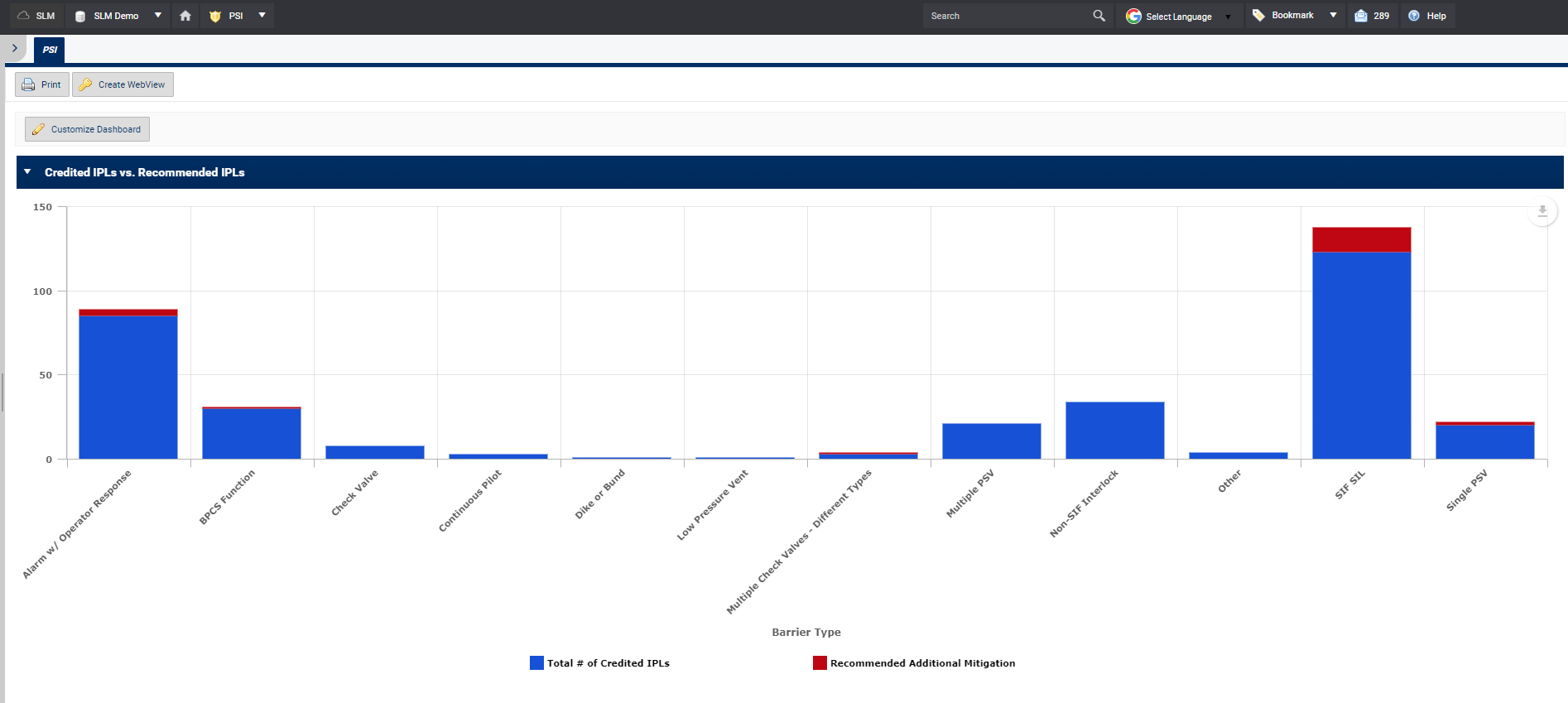

- Credited IPLs vs. Recommended IPLs

- Dynamic Risk Matrix

- IPL Assessment Overview

- IPL Credit Breakdown

- IPL Credit By Unit Type

- LOPA Critical Equipment List

- LOPA IPL Register

- LOPA Recommendations

- LOPA Sheets with Open Recommendations

- LOPA Worksheets List

- Safety Critical Instrument List

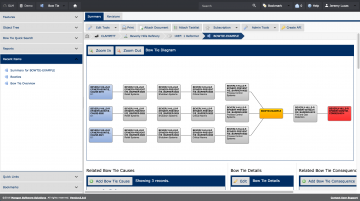

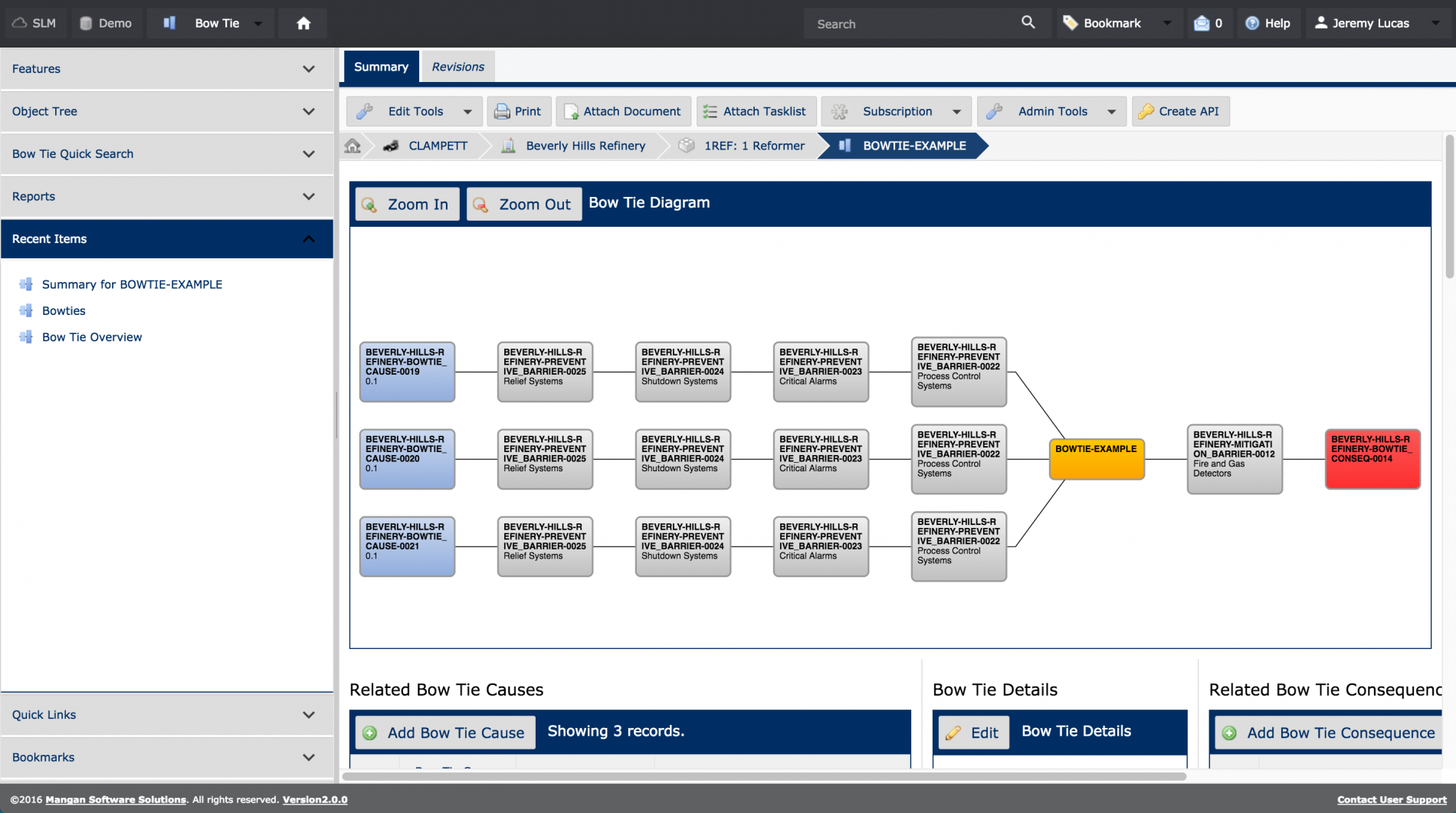

BowTie Barrier Assurance

Click Image to Zoom

- Automatically create Bow Ties using existing LOPA data

- Data linkage to other modules

- Bow Tie analysis assessment checklist

- Intuitive graphical interface

- Add unlimited threats, mitigations, and consequences to the top hazard event

- Export via PDF or Excel

- Barrier Assurance checklists and workflows

SLM V2 BOWTIE BARRIER ASSURANCE DATA OUTPUTS AND REPORTS

The following Data and Reports are part of the SLM V2 core BowTie Barrier Assurance Module.

Managed BowTie Barrier Assurance Data:

- Hazard

- Causes

- Preventative Barriers

- Barrier Assurance Checklists for Preventative Barriers

- Consequences (Type, Effectiveness, Criticality)

- Mitigation Barriers (Type Effectiveness, Criticality)

- Barrier Assurance Checklist's for Mitigation Barriers

- Bow Tie Task Lists

BowTie Barrier Assurance Reports:

- Bow Ties

- Bow Ties Fit For Service Results

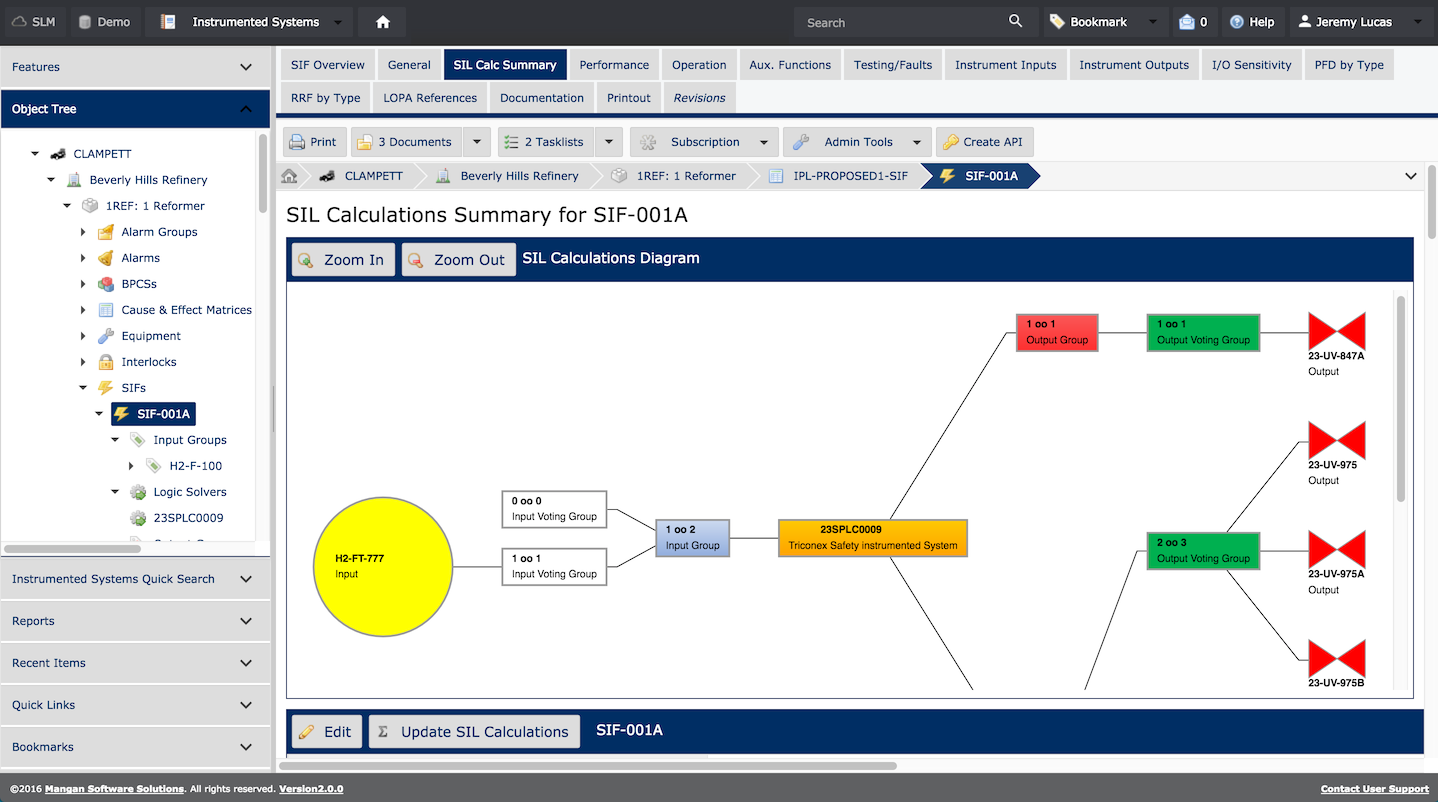

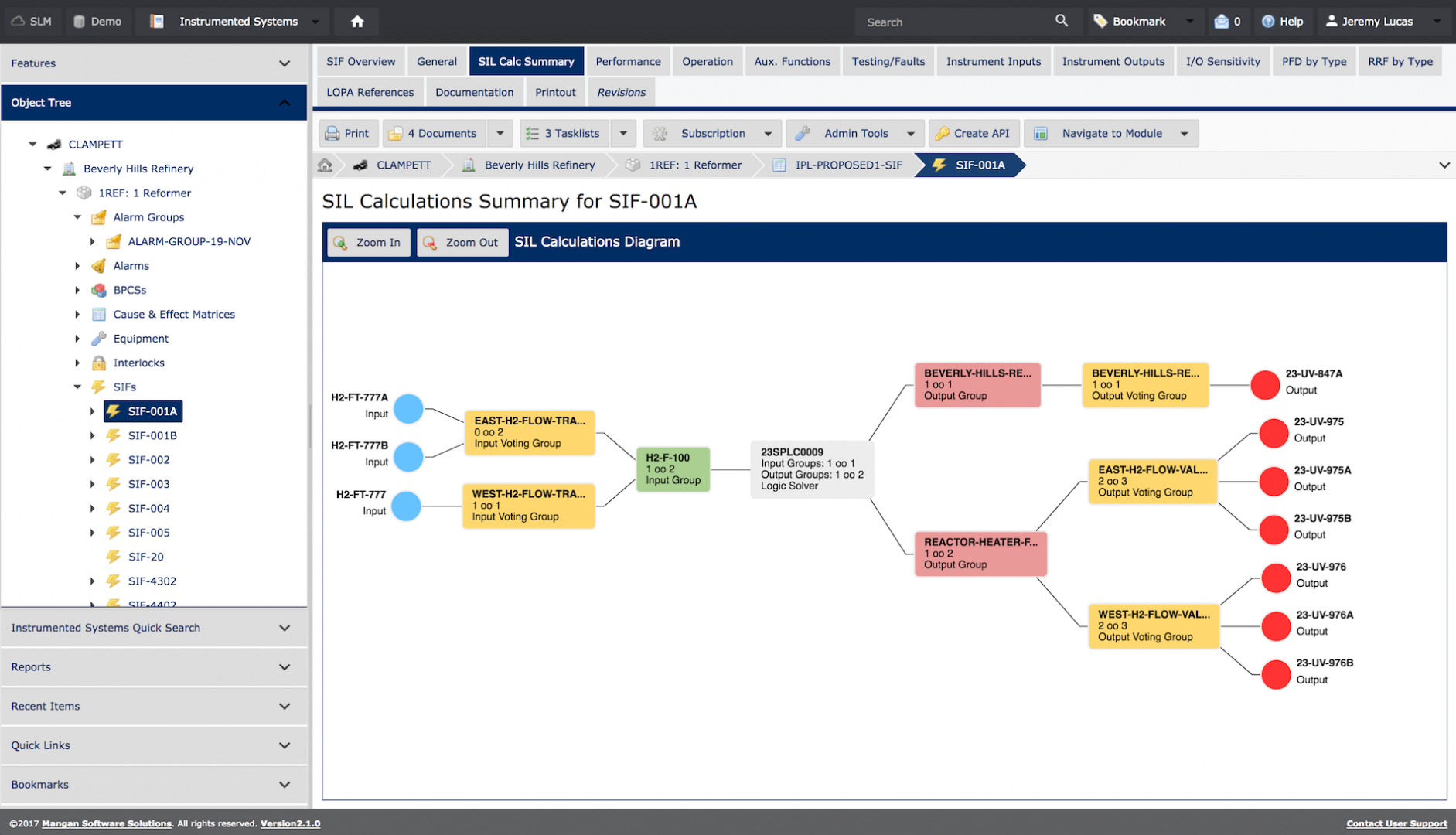

Instrumented Systems

Click Image to Zoom

- Record engineering data for instrument-related risk protection systems

- Automate generation of protective systems registers with differentiation between kinds of systems

- Link safety functions to LOPA scenarios

- Identify safety critical instrumentation with linked risk scenario data

- Automate incorporation of design checklists during system identification/design

- Configure, build, edit and view SRSs

- Track SRS completion with automated completion KPI

- Build instrumented system architectures with sensor/final element voting structures

- Execute SIL calculations on instrumented systems with SLM’s TUV-certified SIL Calc engine

- Evaluate SIL calculation results from multiple failure rate sources at once

- Utilize prior use component failure rates in the SIL calculations from compiled event data in SLM’s Operate/Maintain module

- Optimize system component testing requirements with sensitivity graphs

- Compare SIL calculation results with calculated target requirements from risk scenario data

- Render the system’s architecture in a function diagram displaying logical view of the system’s sensor and final element voting

- Save well-designed systems as templates to use in other operational areas

- Generate cause & effect matrices automatically from designed instrumented system

SLM INSTRUMENTED SYSTEMS MODULE DATA & REPORTS

The following Data and Reports are part of the SLM V2 core Instrumented Systems Module.

Managed Instrumented Systems Data:

- Function Type Summary (Enterprise, Site, Operating Unit)

- Associated IPL's

- Associated Documents

- Alarms

- BPCSs

- Cause & Effect Matrices

- Equipment

- Interlocks

- SIFs

- SIL Calc Summary

- Performance

- Operation

- Aux Functions

- Testing/Faults

- Instrument Inputs

- Instrument Outputs

- I/O Sensitivity

- PFD by Type

- RRF by Type

- LOPA References

- Associated Documentation

- SIF SRS Printout

- SISs

- Functional Requirements

- Design Requirements

- Testing Requirements

- LOPA References

- Associated IPL's

- Task Lists and Summary's

- Input Lists

- Output Lists

Instrumented Systems Reports:

- Alarm Asset Protection Category Report

- Alarm Group Asset Protection Category Report

- BPCS Asset Protection Category Report

- Document List

- Function Type Summary

- Generic SIF Templates

- Input/Output Asset Types

- Interlock Asset Protection Category Report

- SIF Asset Protection Category Report

- SRS Completion

- SIF Printout / Report (SSRS)

Process Safety Intelligence

Click Image to Zoom

- Import PHA data from other sources

- Configure PHA facilitation tables to company standards and procedures

- Conduct project PHAs with option to include the results with the PHA of record

- View PHA risk assessment results by different levels of scope, such as plant, area, and unit

- Configure and organize user interface tables to fit style preference

- Link process equipment to PHA scenarios to determine equipment at risk

- Plot hazardous scenarios on SLM’s Dynamic Risk Matrix

- Track PHA recommendation gap closures

- Automatically generate Barrier lists as PHA scenarios are documented

- PHA Facilitation Report that lists all PHA Nodes, Deviations, and Scenarios in one complete output to review, email, print, and share with your team or across the organization

- PHA Recommendations Report that shows all recommendations from a PHA in a simple filterable display to help identify the areas of highest priority for resolution and further study

- Generate Critical Equipment List Report that quickly identifies which equipment is critical to plant safety and how that equipment is covered

- Initiate PHAs directly from the plant hierarchy at the unit level to quickly start PHA studies and drive operational awareness

The following Data and Reports are part of the SLM V2 core PSI Module.

Managed PSI Data:

- PHA Studies by Site, and Operational Unit

- HAZOP Study Types (HAZOP of Record, Project, Re-Evaluation)

- HAZOP Dynamic Risk Matrix

- HAZOP Dynamic Risk Report

- Study Properties

- Team Participants

- Sessions

- Nodes

- Study Equipment

- Deviations

- Scenario Causes

- Scenario Consequences

PSI Reports:

- Credited IPLs vs. Recommended IPLs

- Dynamic Risk Matrix

- IPL Assessment Overview

- IPL Credit Breakdown

- IPL Credit By Unit Type

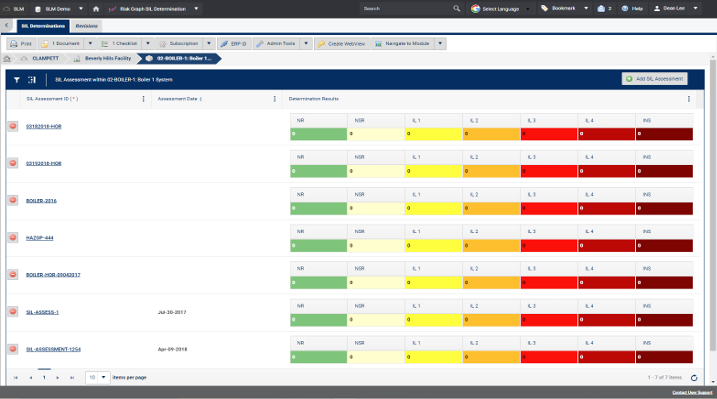

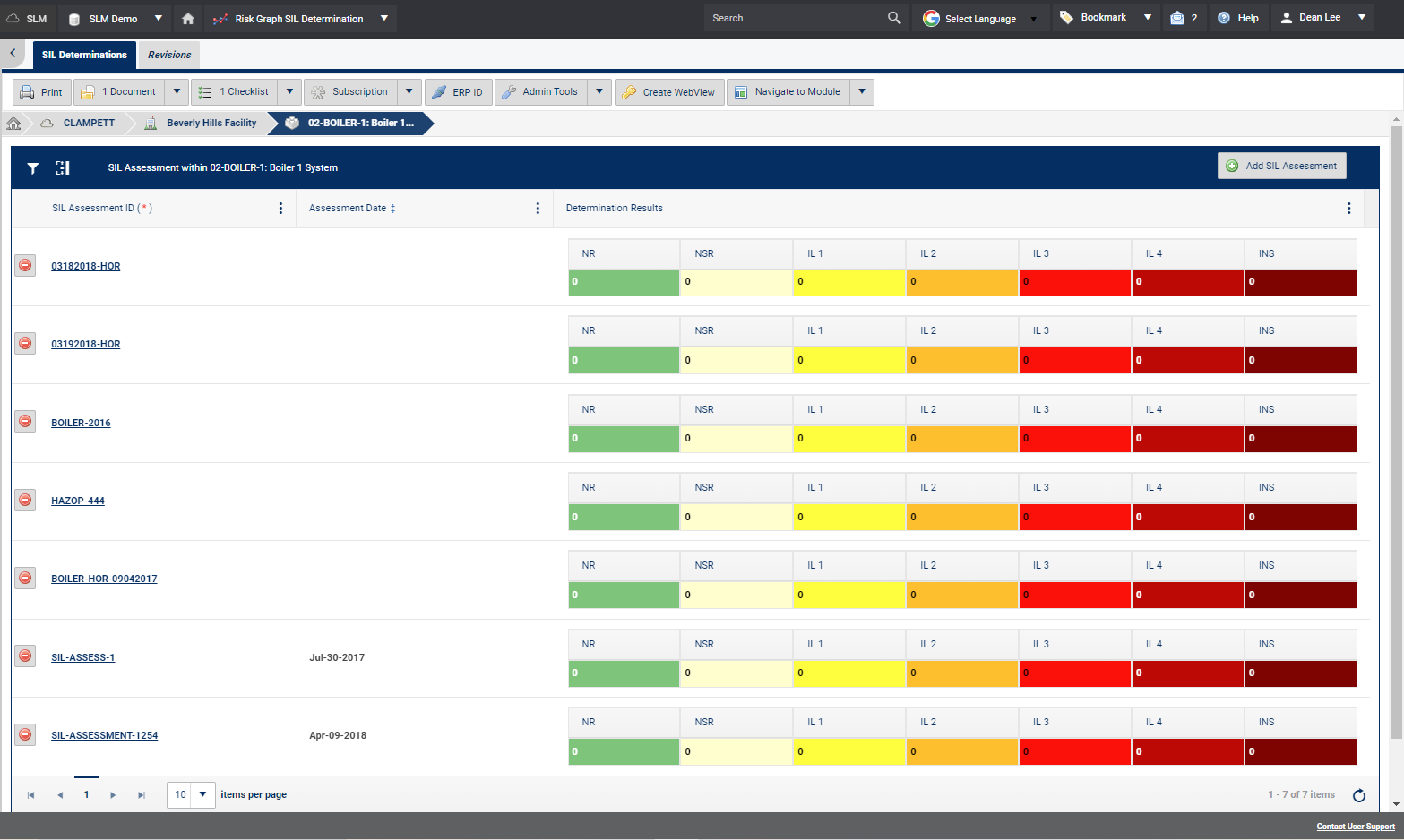

Risk SIL Graph

Click Image to Zoom

Determining the necessary reliability of your safety functions is a key part of assessing your ability to mitigate hazards. The Risk Graph SIL Determination module provides the ability to find existing documented hazardous scenarios and, utilizing user defined scenario parameters, calculate the level of integrity that is required to mitigate the hazardous scenario. Using SLM® software’s modular integration, the determined required integrity level of a scenario can then be applied to a Safety Instrumented Function that will use the determined SIL as its design targets.

- Define SIL Determination parameters per SIL Graph study (Occupancy, Avoidance, Demand Rate, Consequences)

- Automatically calculate the SIL mitigation required

- Create SIF based on SIL required

- SIFs directly connected to the Risk Graph consequence

RISK SIL GRAPH’S MODULE DATA & REPORTS

The following Data and Reports are part of the SLM V2 core Risk SIL Graph Module.

Managed Risk SIL Graph Data:

- SIL Graph studies

- Occupancy

- Avoidance

- Demand Rate

- Consequences

- SIFs

Risk SIL Graph Reports:

- Unit and site level SIL Graph reports

- SIL Determination and facilitate report

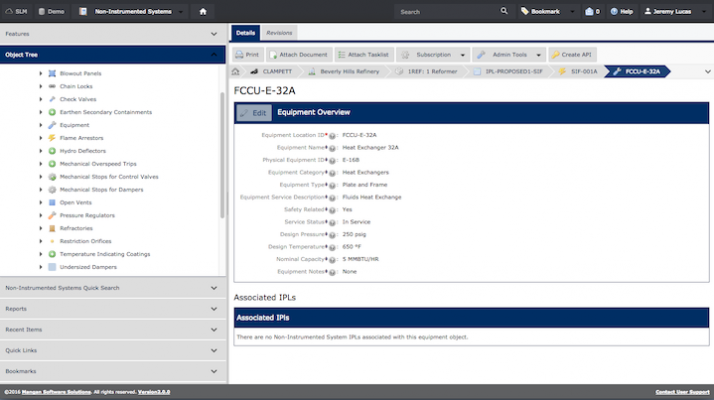

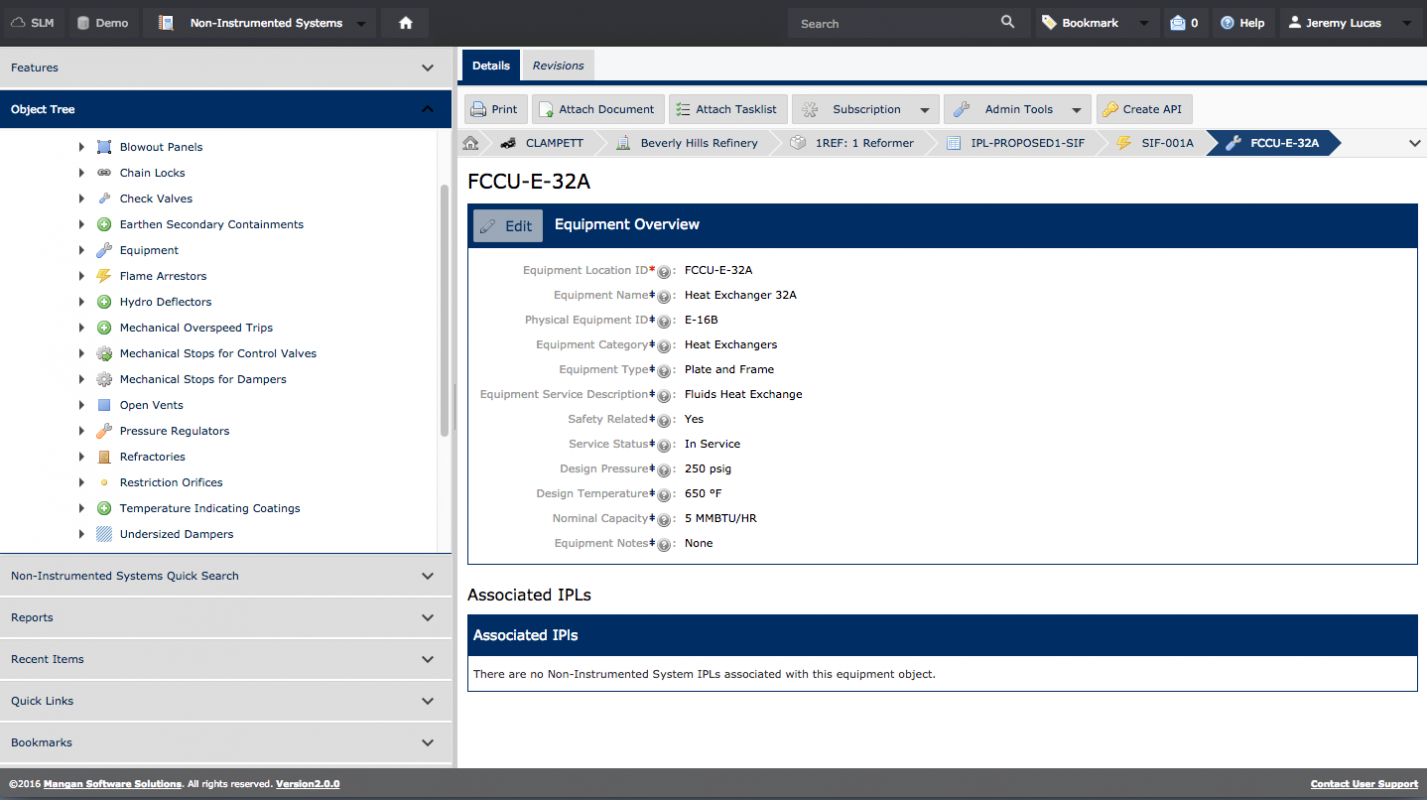

Non-Instrumented Systems

Click Image to Zoom

- Registers for all non-instrumented, non-relief valve devices

- Attach documents

- Configure SLM data tables to link non-instrumented protective systems with barriers

- View associated barrier and LOPA data

- Apply customizable task lists to any safety-related component in the system

SLM NON-INSTRUMENTED SYSTEMS MODULE DATA & REPORTS

The following Data and Reports are part of the SLM V2 core Non-Instrumented Systems Module.

Non Instrumented Systems Data Objects:

- Blowout Panels

- Chain Locks

- Check Valves

- Earthen Secondary Containments

- Equipment

- Flame Arrestors

- Hydro Deflectors

- Mechanical Overspeed Trips

- Mechanical Stops for Control Valves

- Mechanical Stops for Dampers

- Open Vents

- Pressure Regulators

- Refractories

- Restriction Orifices

- Temperature Indicating Coatings

- Undersized Dampers

- Vacuum Breakers

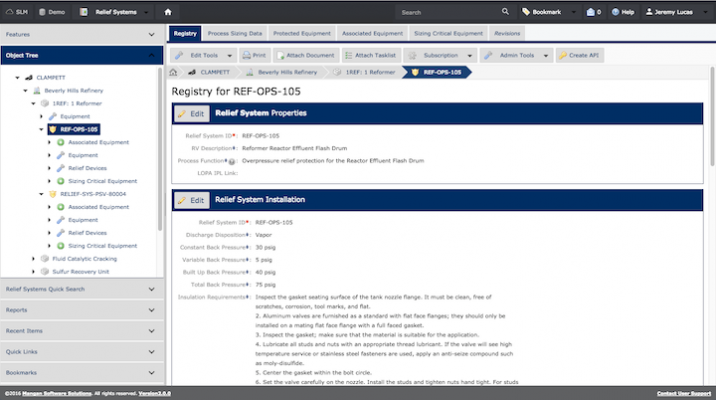

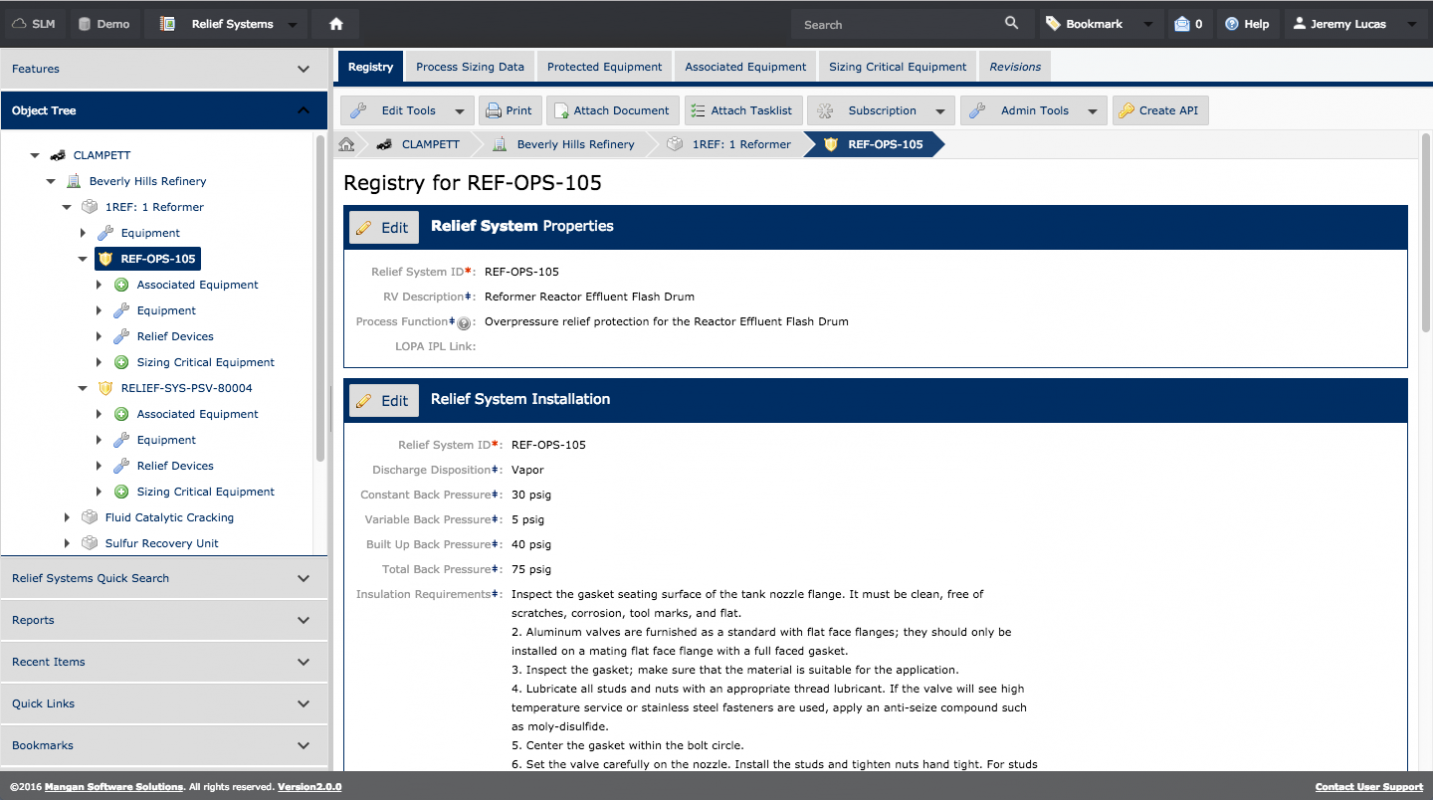

Relief Systems

Click Image to Zoom

- Relief system devices data sheets

- Relief system and equipment registers

- Sync barriers identified in LOPA with relief systems

- Use task lists for relief system engineering checks

- Track associated equipment (block valves and other relief system accessories)

- Relief System test procedure tracking

SLM RELIEF SYSTEM MODULE DATA & REPORTS

The following Data and Reports are part of the SLM V2 core Relief Systems Module.

- Relief System Objects

- Process Sizing Data

- Equipment

- Associated Equipment

- Sizing Critical Equipment

- Block Valve

- Control Valve Limit Stops

- High Integrity Pressure Protective Systems (HIPPS)

- Pipe Spool

- Pump Impeller

- Restriction Orifice Plate

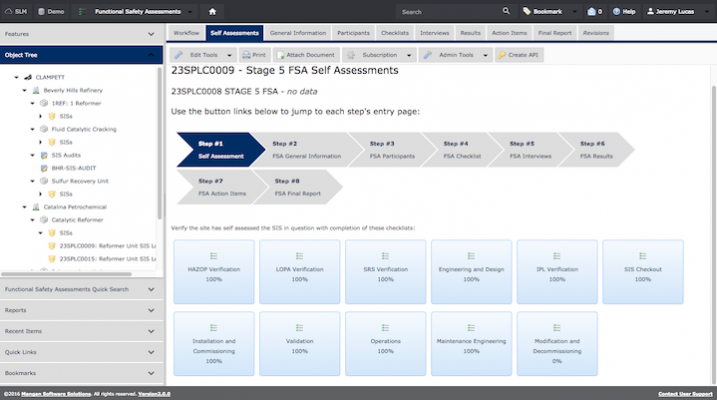

Functional Safety Assessments (FSA)

Click Image to Zoom

The integration of all Safety Life Cycle data provided by SLM also allows for effective integration of FSA data with other critical data such as HAZOP and LOPA studies, Safety Requirements Specifications and SIS performance.

- Perform FSAs

- Perform site assessments

- Perform SIS audits

- Standardize or modify FSA checklists

- Track completion using checklists for self and external SIS assessments

- Compare self-assessments with external assessments

- Track Action Items identified during execution of FSA

- Automatically generate FSA Final Report

SLM FUNCTIONAL SAFETY ASSESSMENT (FSA) MODULE DATA & REPORTS

The following Data and Reports are part of the SLM V2 core Functional Safety Assessments Module.

Data:

- Functional Safety Plan

- Organogram of Safety Plan and Roles

- FSA Overview

- Self Assessment Overview

- SIS Audit Overview

- KPI CAS Overview

- 3 Stage, 4 Stage, 5 Stage FSA Workflows

- Action Item Assignment and Resolution

- Participants

- Introduction and Summary

- Checklists

- Interviews

Reports:

- Functional Safety Plan Report

- Functional Safety Assessment Report

- FSA Checklists Completion

- FSA SSRS Final Report

Operate and Maintain (O&M)

Click Image to Zoom

- Failure analysis and demand tracking

- Overdue test tracking

- Turnaround test tracking

- Barrier bypass/override risk assessments

- Maintenance proof test results and tracking

- Key performance indicators and dashboards

- Configure instant reports (weekly, monthly) to organization standards

- Compile event data over time into prior use data

- Inspection and maintenance planning

- Workflows for documenting: Bypass/Override Procedure, Demand Events, Fault/Failure Reporting, Preventive Maintenance Result Reports and Test Events

- API-RP-754 Tier III Metrics are implemented as a way of tracking challenges to safety systems, such as measures to log large consequence events

- Main Dashboard presents a widget-based selection of KPIs/Reports displayed as windowpanes that default to the user’s account role

- Approval Workflow for Event feature allows Personnel objects associated with a user account to approve or reject events through a series of steps

- Administration reporting available for executing data curing to highlight and enter missing data necessary for optimizing operations data reporting and KPI generation

- A myriad of general, operational, and testing reports provides thorough views of organized and compiled operations data with navigation links to instantly open specific and more granular data

- Categorization of reports allows for quick grouping and simplification of more than 60 basic reports to keep report navigation organized and effortless

- Organize Pending Approvals into a single page view that summarizes all the Pending Events at various levels of the organization

- Automatic periodic statistic updating refreshes data fields related to Testing and Performance of protective systems and their instrument components

- Test Event Workflows allow Functions and Devices to be tested independently from each other

- Integrate protective systems and components with data historians such as PI to automate capturing of real-time events such as demands and bypasses for immediately observed effects on performance and reliability of documented systems

SLM V2 OPERATE AND MAINTAIN DATA & REPORTS

The following Data and Reports are part of the SLM V2 core Operate and Maintain Module.

DATA

- Overview

- Enterprise Overview

- SIS List

- Functions and Events

- Bypass Summary

- Test Summary

- Demand Summary

- Fault/Failure Summary

- Device List

- Generic Models

- Device Type Performance

- IPL List

- Tier III Summary

- Tier III Scorecard

- Tier III Data

- Bad Actors

REPORTS

-

General

-

Availability

-

Bypass Events

-

Bypass Override Procedure Worksheets

-

Current Bypasses

-

Demand Events Recorded

-

Demand Rates

-

Device Event Summary: INPUTS

-

Device Event Summary: OUTPUTS

-

Device List

-

Device Summary: INPUTS

-

Device Summary: OUTPUTS

-

Devices Last Event Failed

-

Devices with Events Prior to Install Date

-

Devices with No Events

-

Equipment Scorecard

-

Event Type Summary

-

Failure Distribution By Generic Model

-

Failure Distribution By Generic Model Graph

-

Failure Distribution by Site

-

Failure Rates

-

Failure Summary

-

Generic Models/Prior Use Statistics

-

INPUTS Failure Rates

-

Install Count and Hours in Service by Gen. Model

-

IPL List

-

List Interlocks and MPs

-

List Interlocks/Inputs/Outputs and MPs

-

List SIFs and TGs

-

Lists Alarms and TGs

-

Lists BPCS and TGs

-

OUTPUTS Failure Rates

-

Periodic Performance Report

-

PIU Dataset Change Report

-

Proven In Use Statistics

-

SIF/SIS/Logic Solver with no Test Groups

-

SIFs with TGs Test Intervals

-

Specific Input Devices By Unit

-

Specific Output Devices By Unit

-

Spurious Trip

-

Test Group IPLs and Devices

-

Test Groups by Overdue and On Schedule

-

Test Groups with no I/O

-

Test Groups with no Last Test date

-

Tests Groups Due

-

Tier III Summary

-

Tier Scorecard

-

Upcoming Tests

-

Upcoming Tests Look Ahead

-

-

Operational

-

Bypasses Summary/Status

-

Demands

-

Fault/Failure Summary/Status

-

-

Testing

-

Test Group List

-

Test Summary/Status Reports

-

-

Administration

-

Device Event Summary

-

Device Performance by Type

-

Device Service Status

-

Devices Without Generic Model

-

Devices Without Model No./Serial No./Service Class

-

Devices Without Test Groups

-

Functions Service Status

-

Functions Without Devices

-

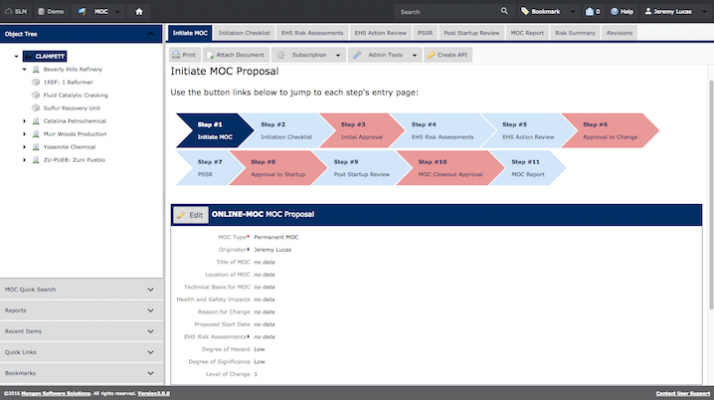

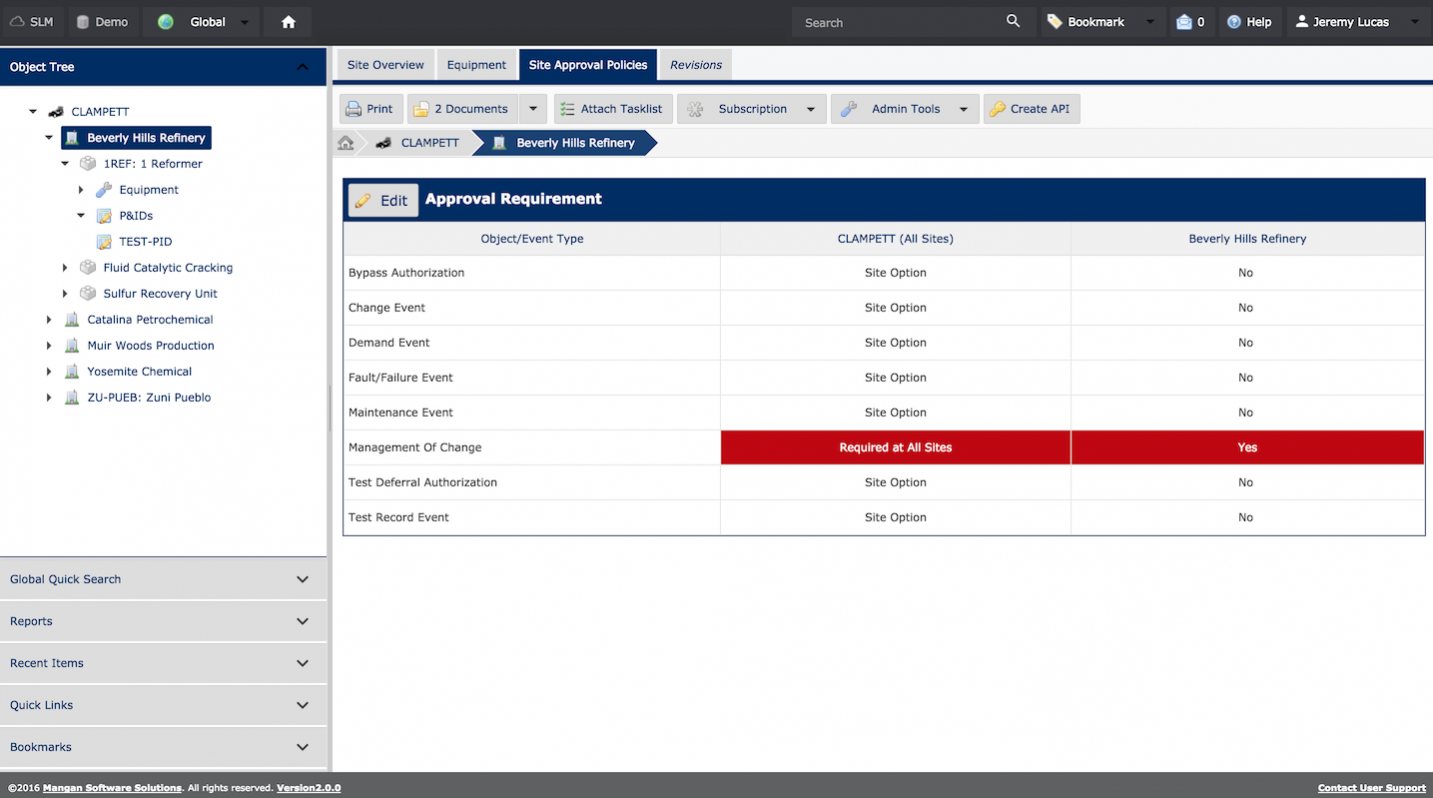

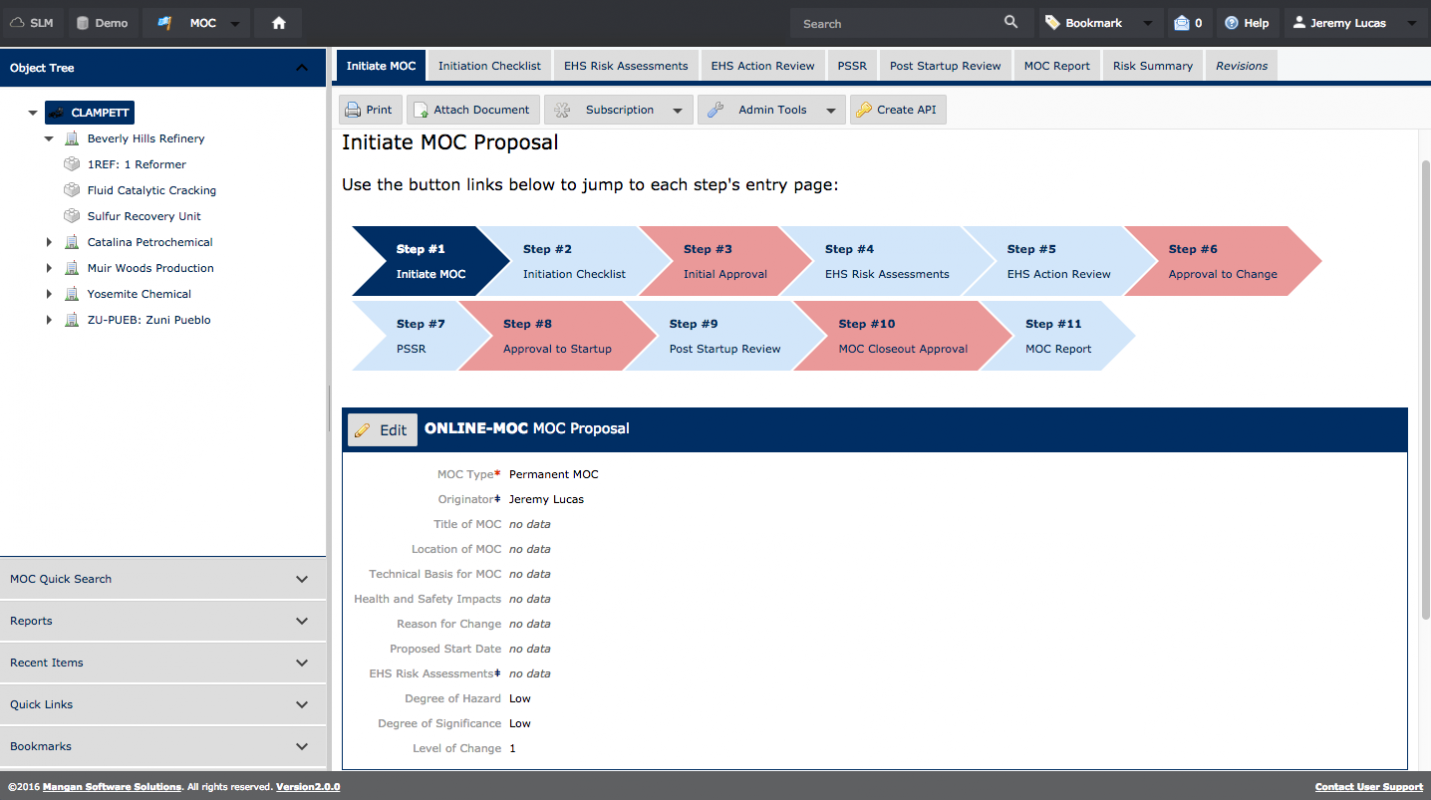

Management of Change (MOC)

Click Image to Zoom

- Links to PSI: HAZOP, LOPA, Instrumented System, Dynamic Risk Matrix

- Software Workflows: Proceed through MOC with required approval processes

- Configure MOC workflow to company standards and procedures

- Assign action items or checklists

- KPIs and instant reports

- Configurable assessment checklists and data views

- Alert System: Email and text notification

- Temporary and emergency workflows

- Disapproval workflow

- Full revision tracking

- Global search features

- Links to Action Item Tracker and Incident Investigation

- Document Management System

MOC Associated Object Linking with the capability of showing associated HAZOP Nodes and LOPA Analysis per MOC object

SLM V2 OPERATE AND MAINTAIN DATA & REPORTS

The following Data and Reports are part of the SLM V2 core Management of Change Module.

Data:

- MOC Proposal

- Initiation Checklist

- MOC Initial Approval Workflow

- EHS Risk Assessments

- EHS Action Review

- Approval to Change Workflow

- PSSR

- Approval to Startup Workflow

- Post Startup Review

- Closeout Approval Workflow

- MOC Report

Reports:

- Action Items Assigned

- MOC List

- MOC Report

- Open MOCs by Type

- Overdue MOCs

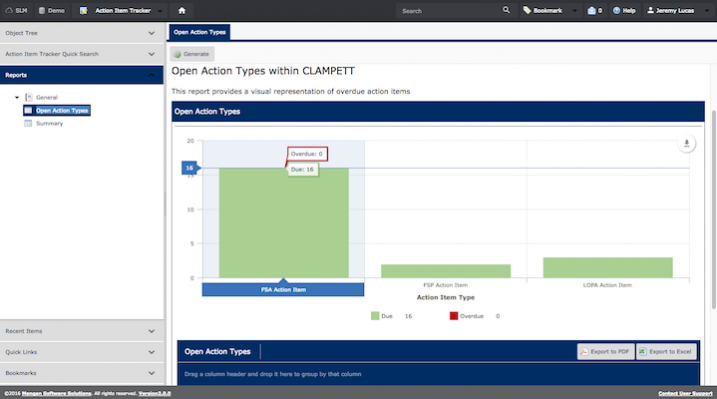

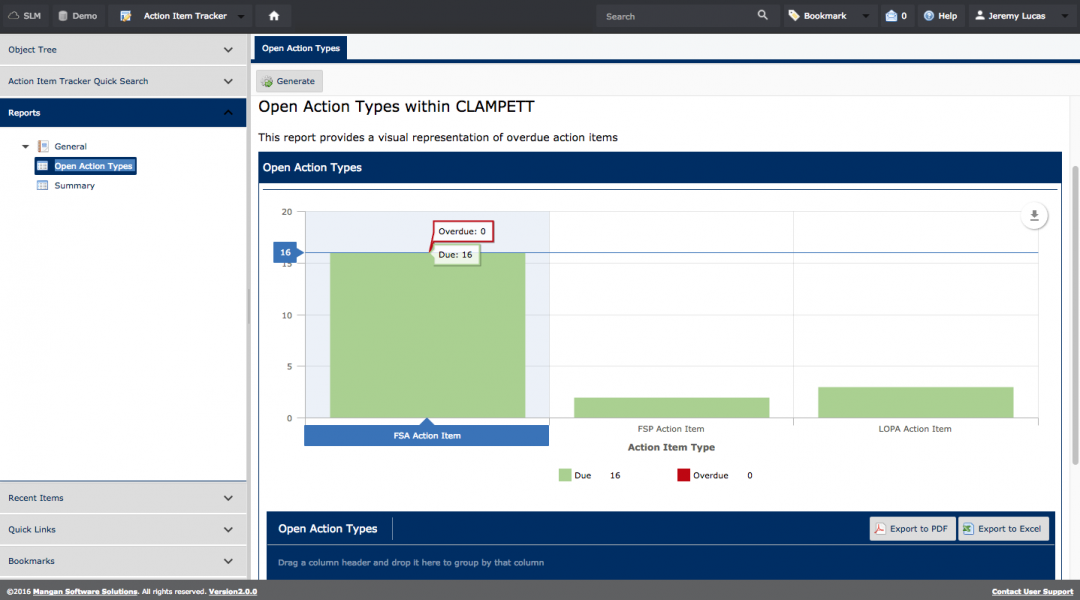

Action Item Tracker

Click Image to Zoom

The Action Item Tracker Module is a centralized location where users can log and access assigned action item information from all modules for follow-up and reporting. Data relating to the action item is linked across modules and readily available for reference purposes.

• Filterable data on enterprise Action Items

• Configurable dashboard and KPI reporting

• Single Source of Knowledge for Action Item Status

• Convenient access to related actions

• Custom fields and configurable Action Item list

• Integration with in-house solutions

• Mobile solutions

• Reporting and file attachments

• Stand Alone Action Items allow for creation of independent action items that utilize the built-in notification system to assign items to system users

SLM V2 ACTION ITEM TRACKER DATA & REPORTS

The following Data and Reports are part of the SLM V2 core Action Item Tracker Module.

Data:

- Action Item Assignment

- Action Item Dashboard

- Personnel Assignment

- Open Action Items

- Closed Action Items

- Action Id

- Date Created

- Category

- Status

- Action

- Reference Contact

- Linked Object Reference

Reports:

- Action Items Assigned

- Open Action Types

- Action Item Summary

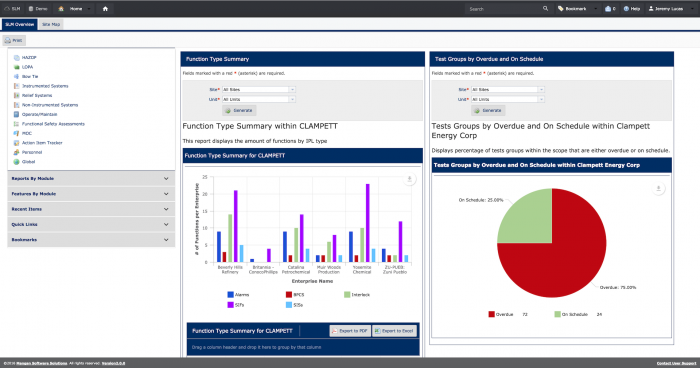

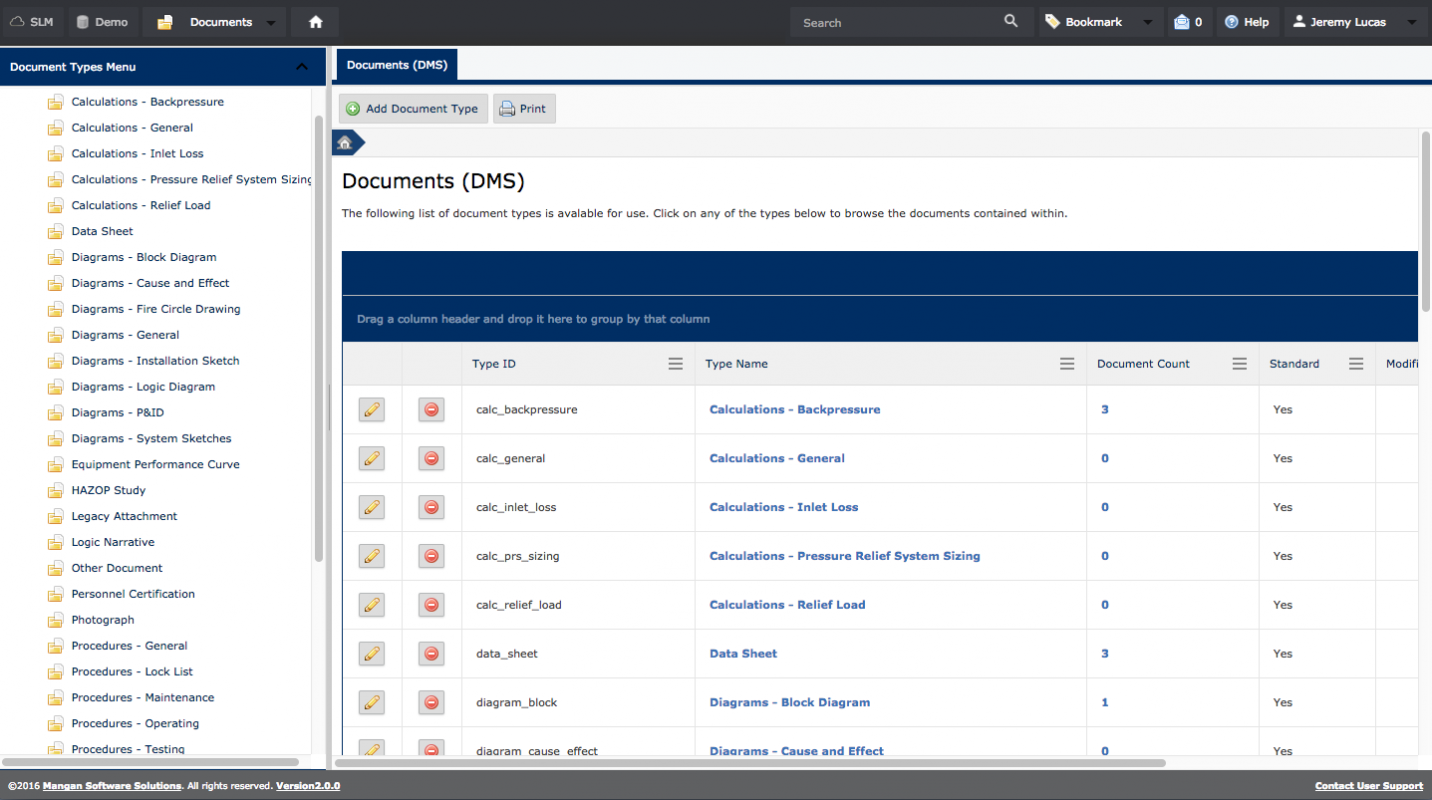

SLM V2 Atlas™ Platform Modules

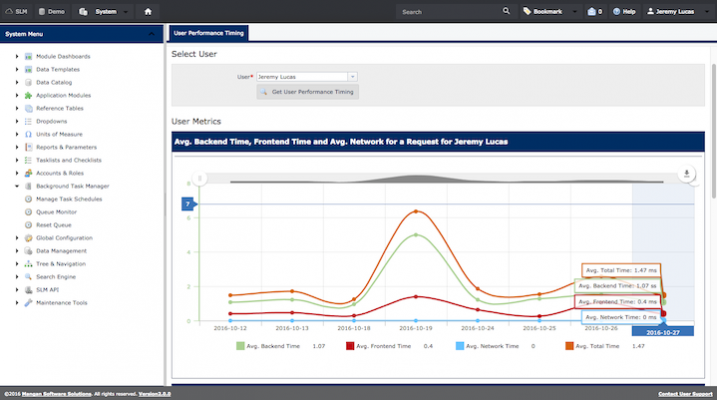

The SLM V2 Atlas™ Platform is the core set of software and technology used to configure, manage data, and site hierarchy across the complete enterprise. Everything from custom UI logo’s, font styling, units of measure, language translation, usage metrics, and API interfaces. To data objects, how they are defined, what they contain, and how they are displayed in the system. These things can all be configured and managed using our software platform.

We have designed our platform to be extensible so that all your data can be stored and managed within our common set of frameworks, as well as extending the platform to suit your enterprise requirements.

- Puts the user in control of what information is important.

- Drag and drop dashboard creation

- Configure the Home Dashboard with more than 150 available reports, data views, and KPI’s throughout the system

- Configure with up to 3 columns of dashboard widgets.

- Access Recent Items, Quick Links, Bookmarks, and Available Modules

- Globally Search the SLM Database for Objects, Data, and Information

- Track and receive notifications on changes for a desired dataset with built-in subscription functionality

- Translate the software views into over 100 different languages

- Create interactive webviews of reports and other views and share with others, including non-users of SLM

- Create and manage plant site hierarchy

- Create and manage areas in a plant

- Create and manage operating units in a site

- Manage approval policies requirements throughout the enterprise

- Manage process equipment globally across the system within each operating site

- Specify site standards for various types of data to include:

- HAZOP Deviations

- Process Equipment Types

- LOPA modifiers such as Conditional Modifiers and Enabling Events

- Configure site-specific risk matrix information to include types of severity, severity values, likelihood values, risk ranking values, and risk mitigation targets, building a site-specific risk matrix in the process for use in the HAZOP and LOPA modules

- Sync site-specific data standards to enterprise-level standards for data conformance option

- Document P&IDs within site and/or process unit level data with ability to upload or link the actual P&ID file

- Specify process unit nodes for PHA node uniformity

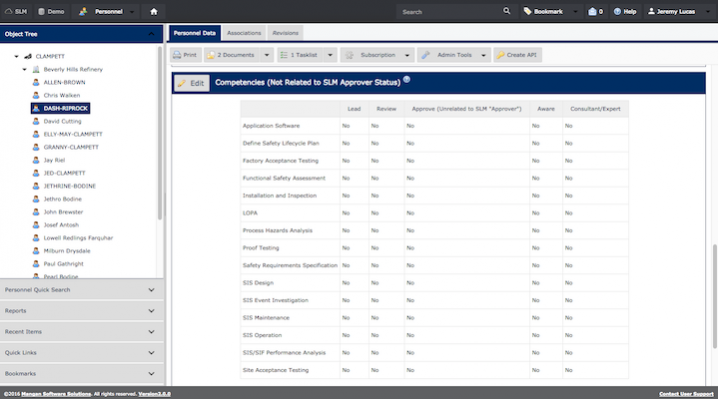

- Manage personnel who will have roles in various parts of the Safety Lifecycle, such as in HAZOP, LOPA, MOC, FSA Studies, and protective systems design

- Document personnel competencies per IEC-61511 regulatory requirements

- Manage personnel who have data approval authority

- Report on personnel competencies

- Document personnel training and certifications

- Implement Functional Safety Plans for operational sites

- Document and track Functional Safety Plan phases and tasks with configurable checklists and personnel roles while linking to associated safety lifecycle data located in other SLM modules

- Assess competencies of personnel applied to Functional Safety Plans

- Track scheduling of Functional Safety Plan phase completion with automatically generated schedule completion charts

- Execute projects in SLM specific to scopes of data selected outset of project definition

- Check-out specific scopes of data from other modules

- Execute and edit project data separated from source data during time of project

- Utilize data templates in project data to speed up project execution

- Identify and restrict data editing and approval capabilities to specific system users

- Review proposed project data changes and approve changes to evergreen data

- Check-in project data to merge approved project data changes with evergreen data

- Apply documents to any data point in SLM

- Specialized document logic models for more than 30 types of documents

- Deep document search to search contents uploaded files to documents

- Configurable document type mappings and rankings

- Remote document linking to external document management system resource URLs

- Tracking of document version and external revisions

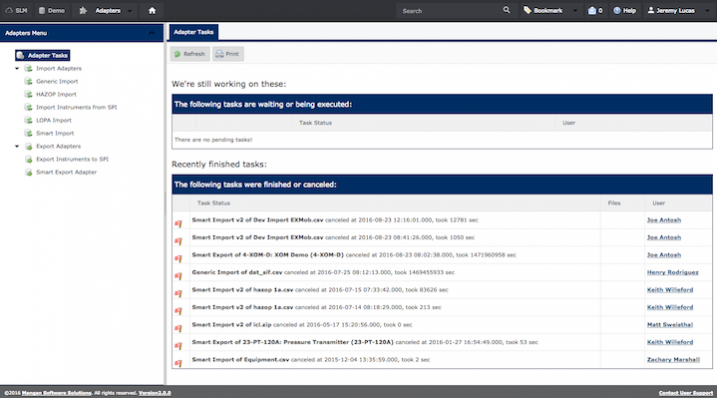

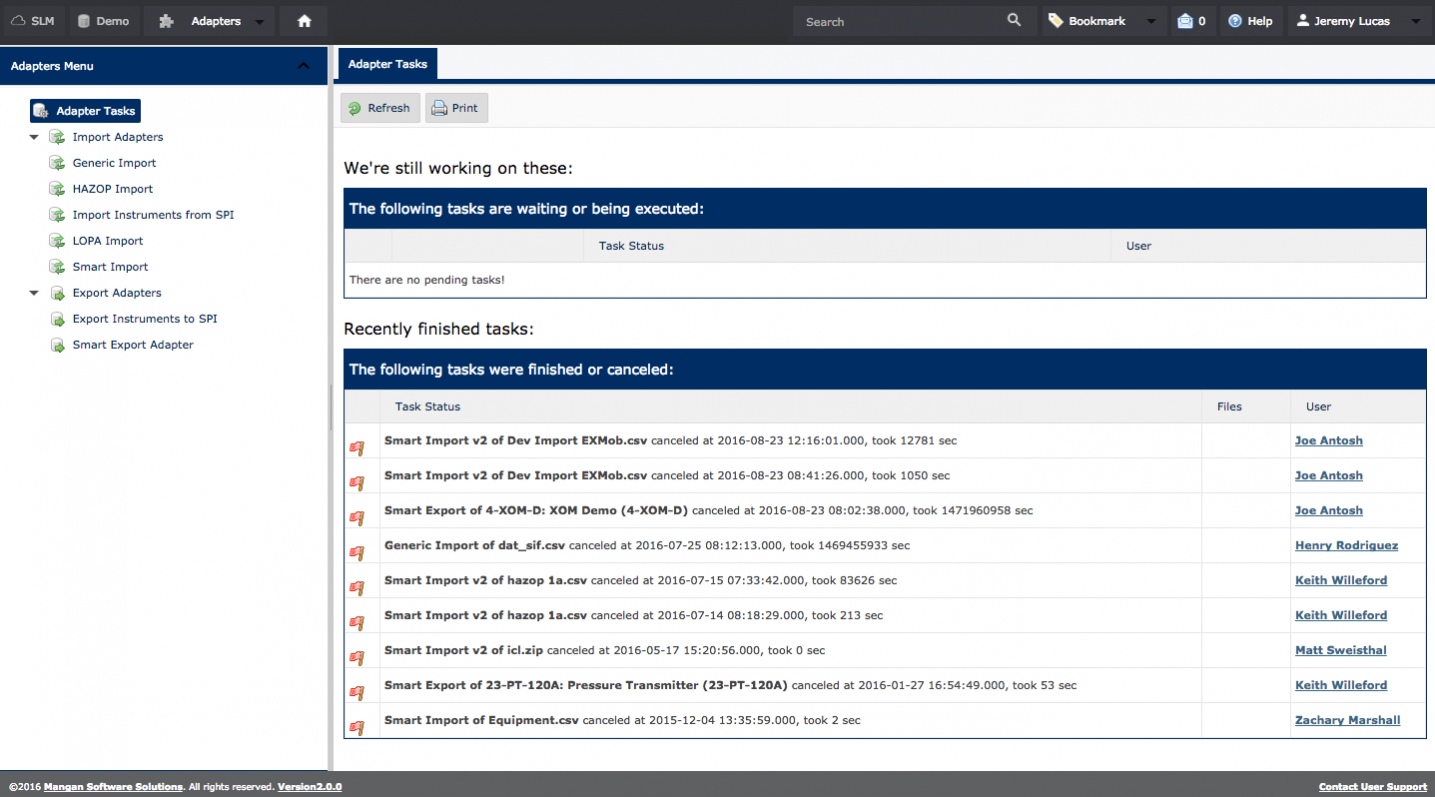

The SLM Import Adapters module is used to import data in SLM to any other module using .csv or .xlsx formatted files. The module allows for defining and storing user configured Import Templates Mappings for batch data importing of data from other systems. Additionally, specialized import adapters are periodically released with SLM versions that ease the effort of importing certain complicated data relationships. Adapters are also available for common data import formats that use a system-generated mapping that requires no user defined mapping.

- Map import files with the system interface guided mapping capability

- Save mapping formats for later use.

- HAZOP and LOPA specialized import adapters allow for importing the default PHA-Pro HAZOP and LOPA database format and fields.

- Detailed Instructions on how to use the Import Adapters and the Smart Export Adapter.

- Import datasets as small as single data points to datasets containing an entire module’s data

- Export datasets from data in any module

- Export and import reference table data to the System Module

- Export data type templates for pre-mapped file formatting, eliminating any user required data mapping effort

- Use the delete adapter to remove multiple specific data points in the system in one effort

|

|

Licensing and Bundles

SLM V2 has a flexible Licensing model allowing you to shape your Safety Lifecycle Solution around your business needs or project goals. We have also built a number of product bundles which group common modules together for specific safety lifecycle management disciplines. Please speak with one of our solutions analysts to help you determine the best fit for your plant or enterprise needs.

Per Module

Per Module Licensing- License only the modules you need

- Includes SLM Atlas Platform Modules

- Flexible Licensing Per Seat, Concurrent User, Site, or Enterprise

- Perpetual Licenses or SaaS Available

- On-Premise Installation, or Securely Hosted on our SLM-Cloud

FSE Bundle

Functional Safety Engineering Bundle- HAZOP, LOPA, Instrumented Systems, Operate & Maintain and Functional Safety Assessment Modules

- Includes SLM Atlas Platform Modules

- Flexible Licensing Per Seat, Concurrent User, Site, or Enterprise

- Perpetual Licenses or SaaS Available

- On-Premise Installation, or Securely Hosted on our SLM-Cloud

PSM Bundle

Process Safety Managment Bundle- HAZOP, LOPA, Bow-Tie, Action Item Tracker

- Includes SLM Atlas Platform Modules

- Flexible Licensing Per Seat, Concurrent User, Site, or Enterprise

- Perpetual Licenses or SaaS Available

- On-Premise Installation, or Securely Hosted on our SLM-Cloud

SLM Full Suite

The Complete Safety Lifecycle- The Complete SLM Safety Lifecycle Suite all Modules

- Includes SLM Atlas Platform Modules

- Flexible Licensing Per Seat, Concurrent User, Site, or Enterprise

- Perpetual Licenses or SaaS Available

- On-Premise Installation, or Securely Hosted on our SLM-Cloud

What Our Customers Are Saying

“BP’s Prior Use vision was to meet compliance at an enterprise level with ANSI/ISA-84 &IEC 16511 and internal standards, and automate the data gathering and calculations to meet these requirements.

With no existing product available on the market, the Mangan Software Solutions team was quick to take the initiative to research, develop, test and refine a system that was able to meet our goals in a matter of weeks.”

“We chose MSS because SLM is the only product on the market that could deliver the functionality we needed to meet our organization’s strategic functional safety goals. The software standardizes and streamlines our methods for developing safety requirements specifications (SRS), completing all necessary approval and verifications protocols, and testing of all SIS devices.”

Our Customers

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

What our Customers are Saving..

16M Cost Savings in First Year!

Average savings of (41$) per process action compared to Sharepoint

10X Reduction in reporting and data gathering hours spent

%

27% Reduction in Costs, While increasing task efficency and performance

Challenges

- Regulations and audit findings in the SIS arena have become more stringent with recent safety incidents, but legacy facilities and antiquated systems make compliance complex and time consuming.

- Disparate systems and home grown databases create user push back to adoption of consistent process safety data and procedures.

- Time consuming data collection combined with non-existent reporting capability hinder informed safety oversight on every level.

Results

- Developed from the ground up with strategic operators after a real-world incident, ProSys encapsulates best practice processes and workflow for the SIS lifecycle, including: HAZOP, LOPA, SRS and FSA.

- ProSys is designed for enterprise wide systematic documentation, auditing and compliance while offering turnkey integration capabilities for prior data formats.

- ProSys’ enhanced data gathering efficiency’s create significant upfront savings while enabling management to mitigate risk through collective knowledge and transparency.

“The new product transcends traditional process safety database software with an integrated design to reduce cost and effort with automated and standardized workflows to execute compliance and engineering processes.” – Control Engineering Magazine

Sign up Today For a Demonstration

Contact us today for a one-on-one demonstration of our award winning safety lifecycle platform.

Mangan Software Video Presentations

Mangan Software SLM Overview

Mangan Software SLM is the single solution to transform all your process safety information into actionable intelligence. By bringing all the data and engineering processes from your process safety, functional safety, and asset integrity disciplines into SLM cloud-based platform, you now have a sustainable and cost-effective approach to continuous safety improvement.

Mangan Software Process Safety Intelligence Platform

The world's first process safety intelligence platform by Mangan Software Solutions.

Functional Safety Assessments - What, Why, When, Who, and Where

Presented by: Zach Marshall (MSS) and Ramon Morillo (Andeavor)

Date: Oct 23, 2017

ISA Webinar Event June 8 2016: Strategy, Tactics and Tools for the Safety LIfecycle

In this webinar, learn how one manufacturing organization approached the challenge of implementing and complying with the ISA84 Safety Lifecycle in existing facilities by adopting new management practices and software tools. What problems did they encounter? What key wins are expected, or have been realized, from the effort?

Stephen Thomas, PE (Chevron)

Alaric Durkan, MBA (MSS)