EPC and Project Solutions

-

Identify protective systems required by hazard analyses along with performance requirements to determine design requirements.

-

Visualize architectural design of safety functions with block diagram capabilities.

-

Instantly perform SIL calculations of safety functions with actual component performance data to compare design against performance requirements.

-

Determine requirements of testing intervals for safety functions with sensitivity charts.

-

Utilize SRS templates to guide uniformity of safety system design and SRS documentation.

-

Automatically generate Cause and Effect Matrices with designed protective systems and the capability to immediately update with changes to system design.

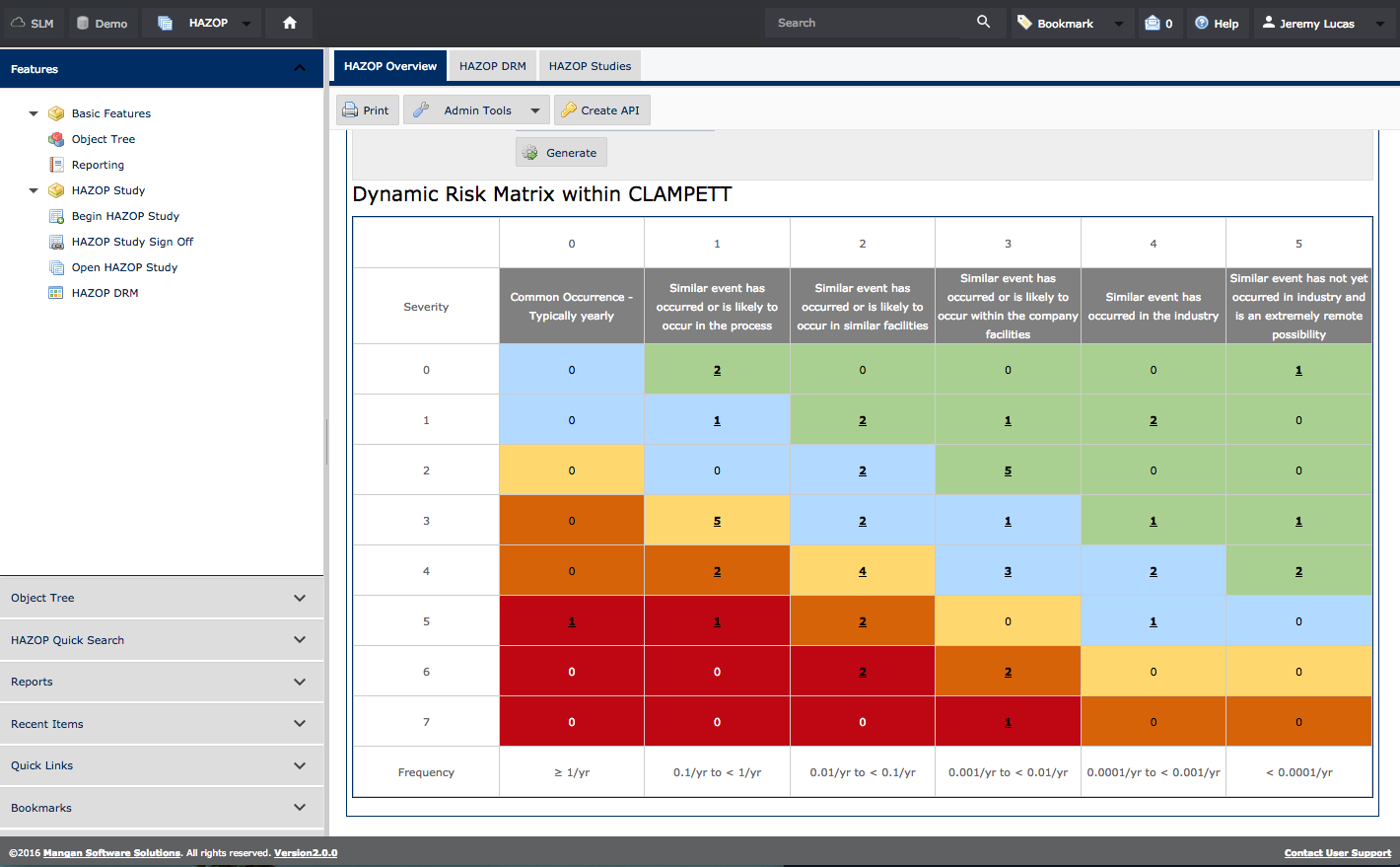

HAZOP

Click on Image to Zoom

- Facilitate HAZOP studies directly in SLM or import HAZOP data from other sources

- Configure HAZOP facilitation tables to company standards and procedures

- Conduct project HAZOPs with option to include the results with the HAZOP of record

- View HAZOP risk assessment results by different levels of scope, such as plant, area, and unit

- Configure and organize user interface tables to fit style preference

- Link process equipment to HAZOP scenarios to determine equipment at risk

- Plot hazardous scenarios on SLM’s Dynamic Risk Matrix

- Link HAZOP scenarios to LOPA module scenario data

- Link safeguarding barriers with protective systems identified in later Safety Lifecycle modules

- Track HAZOP recommendation gap closures

- Automatically generate Barrier lists as HAZOP scenarios are documented

- HAZOP Facilitation Report that lists all HAZOP Nodes, Deviations, and Scenarios in one complete output to review, email, print, and share with your team or across the organization

- HAZOP Recommendations Report that shows all recommendations from a HAZOP in a simple filterable display to help identify the areas of highest priority for resolution and further study

- Generate Critical Equipment List Report that quickly identifies which equipment is critical to plant safety and how that equipment is covered

- Generate Action Items for further analysis or study by the HAZOP team directly from any recommendations, then assign and track the item it to closure

- Initiate HAZOPs directly from the plant hierarchy at the unit level to quickly start HAZOP studies and drive operational awareness

- HAZOP study approval process with email notification

SLM HAZOP DATA OUTPUTS AND REPORTS

The following Data and Reports are part of the SLM V2 core HAZOP Module.

Managed HAZOP Data :

- HAZOP Studies by Site, and Operational Unit

- HAZOP Study Types (HAZOP of Record, Project, Re-Evaluation)

- HAZOP Dynamic Risk Matrix

- HAZOP Dynamic Risk Report

- Study Properties

- Team Participants

- Sessions

- Nodes

- Study Equipment

- Deviations

- Scenario Causes

- Scenario Consequences

- Scenarios with Suggested Safeguards and Recommendations

- HAZOP Recommendations

- HAZOP Safeguards

- HAZOP Report

- HAZOP Approval Workflow

HAZOP Reports:

- Approved HAZOP Study List Dynamic Risk Matrix

- HAZOP Critical Equipment List

- HAZOP Inherent Risk Chart

- HAZOP Recommendations

- HAZOP Re-Evaluation Timeline

- HAZOP Review

- HAZOP Safeguard List

- HAZOP Scenarios Requiring LOPA vs. LOPAs Performed

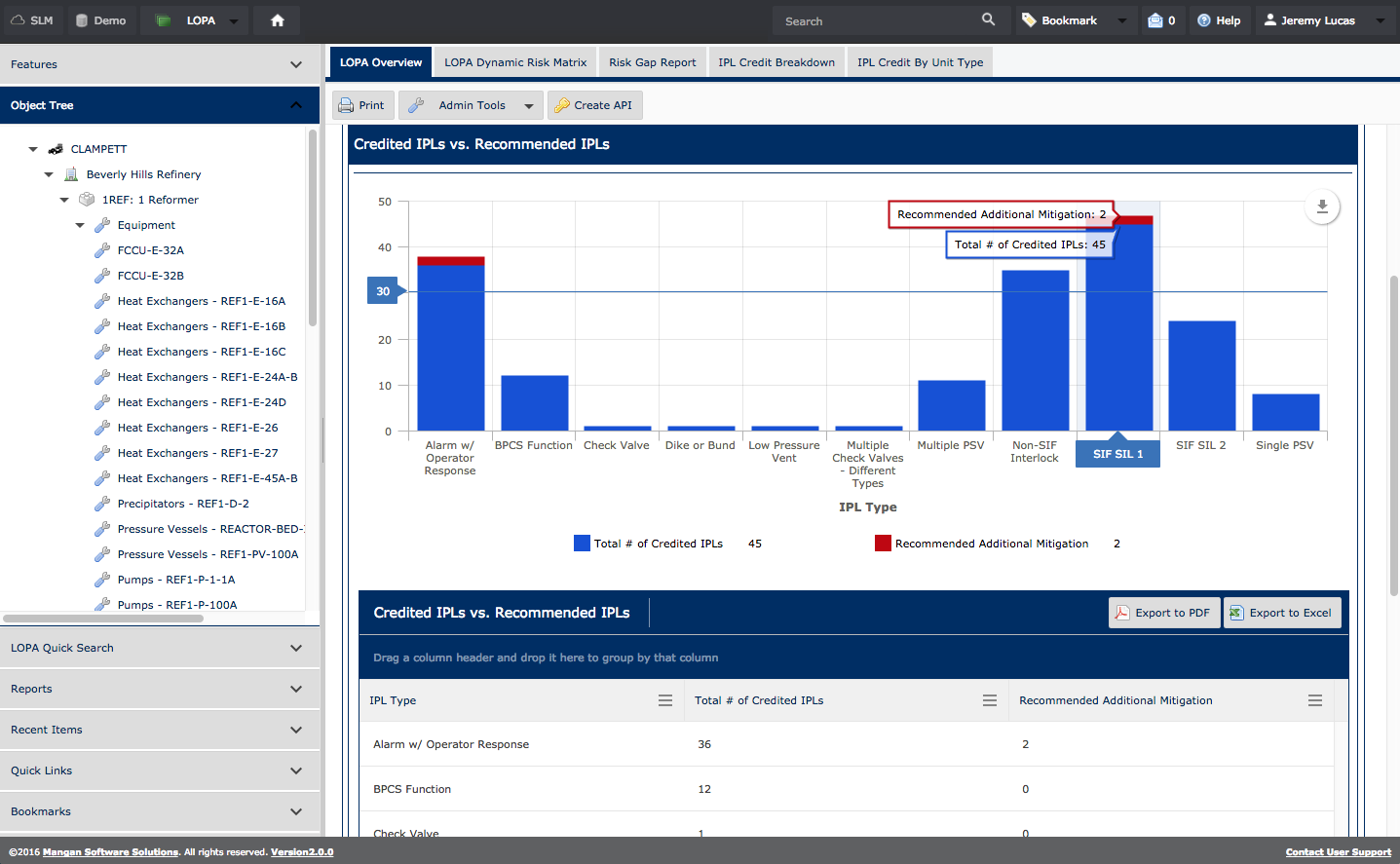

LOPA

Click on Image to Zoom

- Facilitate LOPA studies directly in SLM or import LOPA data from other sources

- Configure LOPA data library tables to company standards and procedures

- Create LOPAs from previously saved LOPA templates

- Link LOPA scenarios with recorded HAZOP module scenarios

- Use same list of barriers as HAZOP module for LOPA scenario mitigation

- Automatically calculate barrier target requirements as LOPA scenarios are documented

- Automatically calculate expected demand rates on barriers

- Combine barrier target requirements across multiple scenarios using the same barrier

- View barrier diagrams displaying sequence of threat propagation through barriers

- Schedule and track scenario and barrier gap closure

- Plot LOPA scenarios on SLM’s Dynamic Risk Matrix showing effect of invalid/inadequate barriers, with option to toggle results to include effects of barriers currently in bypass status

- Link IPL barriers with actual protective systems designed to meet barrier target requirements

- Automatically generate barrier registers from LOPA data

- Track LOPA and barrier recommendations

- Generate Action Items from LOPA recommendations that are automatically added to the Action Item Tracker to ensure all recommendations are mitigated and addressed in a timely manner.

- Generate Critical Equipment List to provide a list of “equipment at risk” identified during a LOPA Study along with the highest risk in each of the equipment's associated LOPA Sheets.

- Filter reports of LOPA scenarios to find specific scenarios containing specific barriers, types of barriers, equipment, and level of severities

- Generate LOPA Recommendations Report to review all recommendations documented within a LOPA Study

SLM LOPA DATA OUTPUTS AND REPORTS

The following Data and Reports are part of the SLM V2 core LOPA Module.

Managed LOPA Data:

- LOPA Dynamic Risk Matrix

- Risk Gap Report Planed Risk Reduction by Year

- LOPA Equipment Listing

- IPL Register (Enterprise, Site and Unit)

- Credited IPL Register (Site, Unit)

- LOPA Recommendations (Site, Unit)

- LOPA Studies

- LOPA Worksheets

- PHA Consequences and Risk Target

- Frequency Modifiers

- Initiating Causes (IC) x Frequency Modifiers

- Independent Protection Layers (IPLs)

- Probability of Failure on Demand (PFD) of SIF

- Potential Risk Reduction Measures

- Remaining Risk Reduction Factor (RRF) with Recommendations

- Notes, Comments, Calculations

- IPL Study Tasklists

- LOPA Recommendations and Action Items

LOPA Reports:

- Credited IPLs vs. Recommended IPLs

- Dynamic Risk Matrix

- IPL Assessment Overview

- IPL Credit Breakdown

- IPL Credit By Unit Type

- LOPA Critical Equipment List

- LOPA IPL Register

- LOPA Recommendations

- LOPA Sheets with Open Recommendations

- LOPA Worksheets List

- Safety Critical Instrument List

Functional Safety Assessments (FSA)

Click Image to Zoom

The integration of all Safety Life Cycle data provided by SLM also allows for effective integration of FSA data with other critical data such as HAZOP and LOPA studies, Safety Requirements Specifications and SIS performance.

- Perform FSAs

- Perform site assessments

- Perform SIS audits

- Standardize or modify FSA checklists

- Track completion using checklists for self and external SIS assessments

- Compare self-assessments with external assessments

- Track Action Items identified during execution of FSA

- Automatically generate FSA Final Report

SLM FUNCTIONAL SAFETY ASSESSMENT (FSA) MODULE DATA & REPORTS

The following Data and Reports are part of the SLM V2 core Functional Safety Assessments Module.

Data:

- Functional Safety Plan

- Organogram of Safety Plan and Roles

- FSA Overview

- Self Assessment Overview

- SIS Audit Overview

- KPI CAS Overview

- 3 Stage, 4 Stage, 5 Stage FSA Workflows

- Action Item Assignment and Resolution

- Participants

- Introduction and Summary

- Checklists

- Interviews

Reports:

- Functional Safety Plan Report

- Functional Safety Assessment Report

- FSA Checklists Completion

- FSA SSRS Final Report

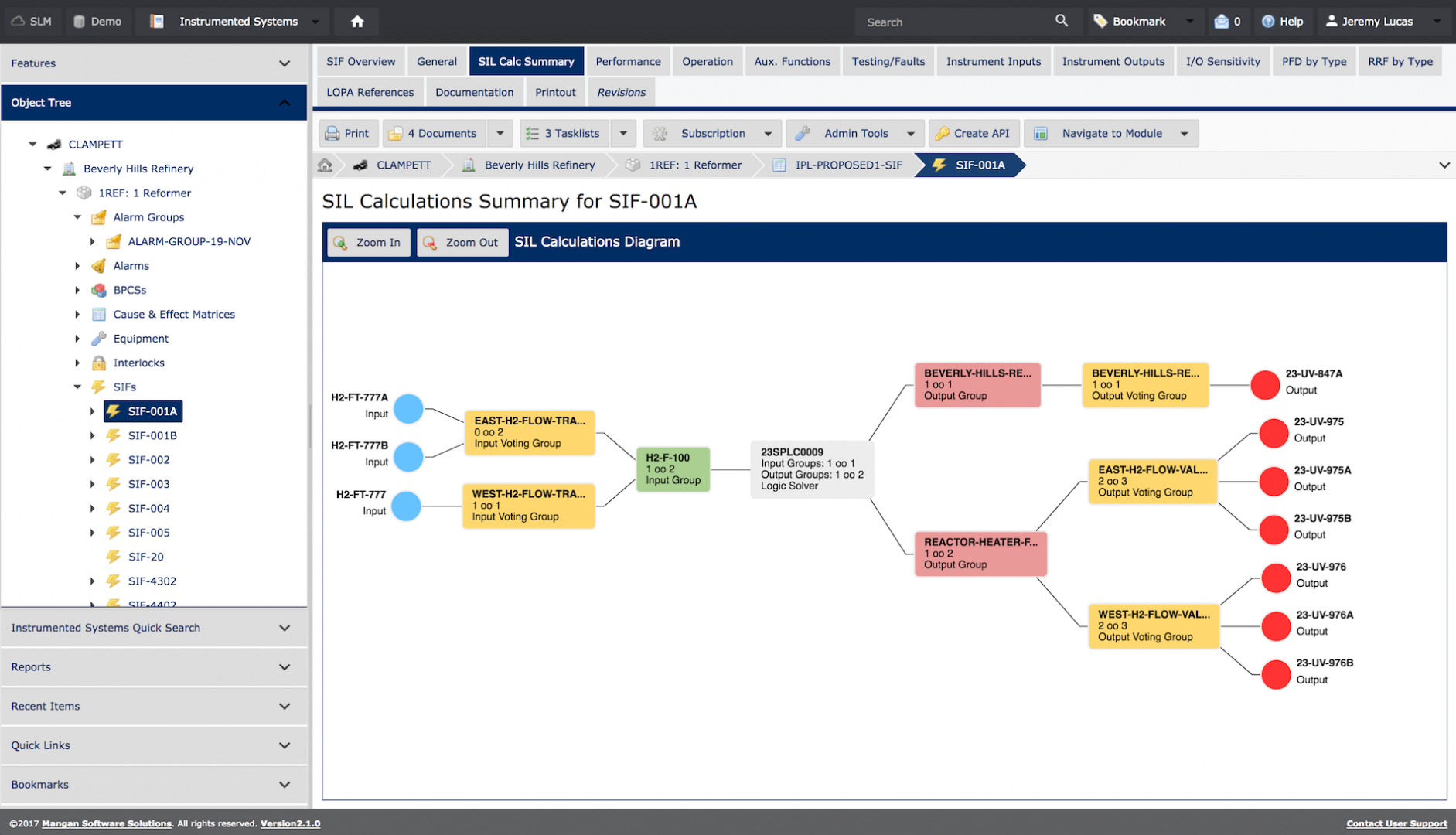

Instrumented Systems

Click Image to Zoom

- Record engineering data for instrument-related risk protection systems

- Automate generation of protective systems registers with differentiation between kinds of systems

- Link safety functions to LOPA scenarios

- Identify safety critical instrumentation with linked risk scenario data

- Automate incorporation of design checklists during system identification/design

- Configure, build, edit and view SRSs

- Track SRS completion with automated completion KPI

- Build instrumented system architectures with sensor/final element voting structures

- Execute SIL calculations on instrumented systems with SLM’s TUV-certified SIL Calc engine

- Evaluate SIL calculation results from multiple failure rate sources at once

- Utilize prior use component failure rates in the SIL calculations from compiled event data in SLM’s Operate/Maintain module

- Optimize system component testing requirements with sensitivity graphs

- Compare SIL calculation results with calculated target requirements from risk scenario data

- Render the system’s architecture in a function diagram displaying logical view of the system’s sensor and final element voting

- Save well-designed systems as templates to use in other operational areas

- Generate cause & effect matrices automatically from designed instrumented system

SLM INSTRUMENTED SYSTEMS MODULE DATA & REPORTS

The following Data and Reports are part of the SLM V2 core Instrumented Systems Module.

Managed Instrumented Systems Data:

- Function Type Summary (Enterprise, Site, Operating Unit)

- Associated IPL's

- Associated Documents

- Alarms

- BPCSs

- Cause & Effect Matrices

- Equipment

- Interlocks

- SIFs

- SIL Calc Summary

- Performance

- Operation

- Aux Functions

- Testing/Faults

- Instrument Inputs

- Instrument Outputs

- I/O Sensitivity

- PFD by Type

- RRF by Type

- LOPA References

- Associated Documentation

- SIF SRS Printout

- SISs

- Functional Requirements

- Design Requirements

- Testing Requirements

- LOPA References

- Associated IPL's

- Task Lists and Summary's

- Input Lists

- Output Lists

Instrumented Systems Reports:

- Alarm Asset Protection Category Report

- Alarm Group Asset Protection Category Report

- BPCS Asset Protection Category Report

- Document List

- Function Type Summary

- Generic SIF Templates

- Input/Output Asset Types

- Interlock Asset Protection Category Report

- SIF Asset Protection Category Report

- SRS Completion

- SIF Printout / Report (SSRS)

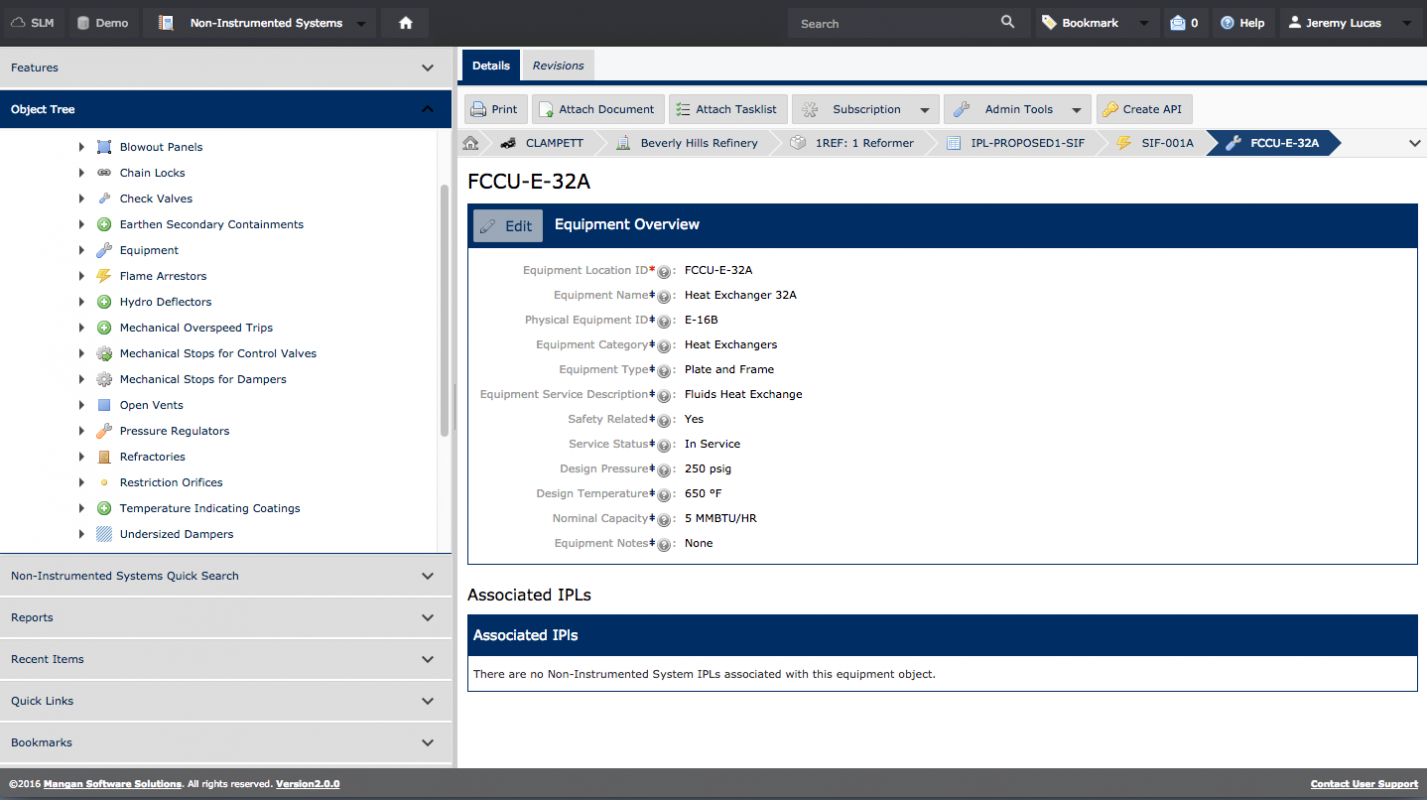

Non-Instrumented Systems

Click Image to Zoom

- Registers for all non-instrumented, non-relief valve devices

- Attach documents

- Configure SLM data tables to link non-instrumented protective systems with barriers

- View associated barrier and LOPA data

- Apply customizable task lists to any safety-related component in the system

SLM NON-INSTRUMENTED SYSTEMS MODULE DATA & REPORTS

The following Data and Reports are part of the SLM V2 core Non-Instrumented Systems Module.

Non Instrumented Systems Data Objects:

- Blowout Panels

- Chain Locks

- Check Valves

- Earthen Secondary Containments

- Equipment

- Flame Arrestors

- Hydro Deflectors

- Mechanical Overspeed Trips

- Mechanical Stops for Control Valves

- Mechanical Stops for Dampers

- Open Vents

- Pressure Regulators

- Refractories

- Restriction Orifices

- Temperature Indicating Coatings

- Undersized Dampers

- Vacuum Breakers

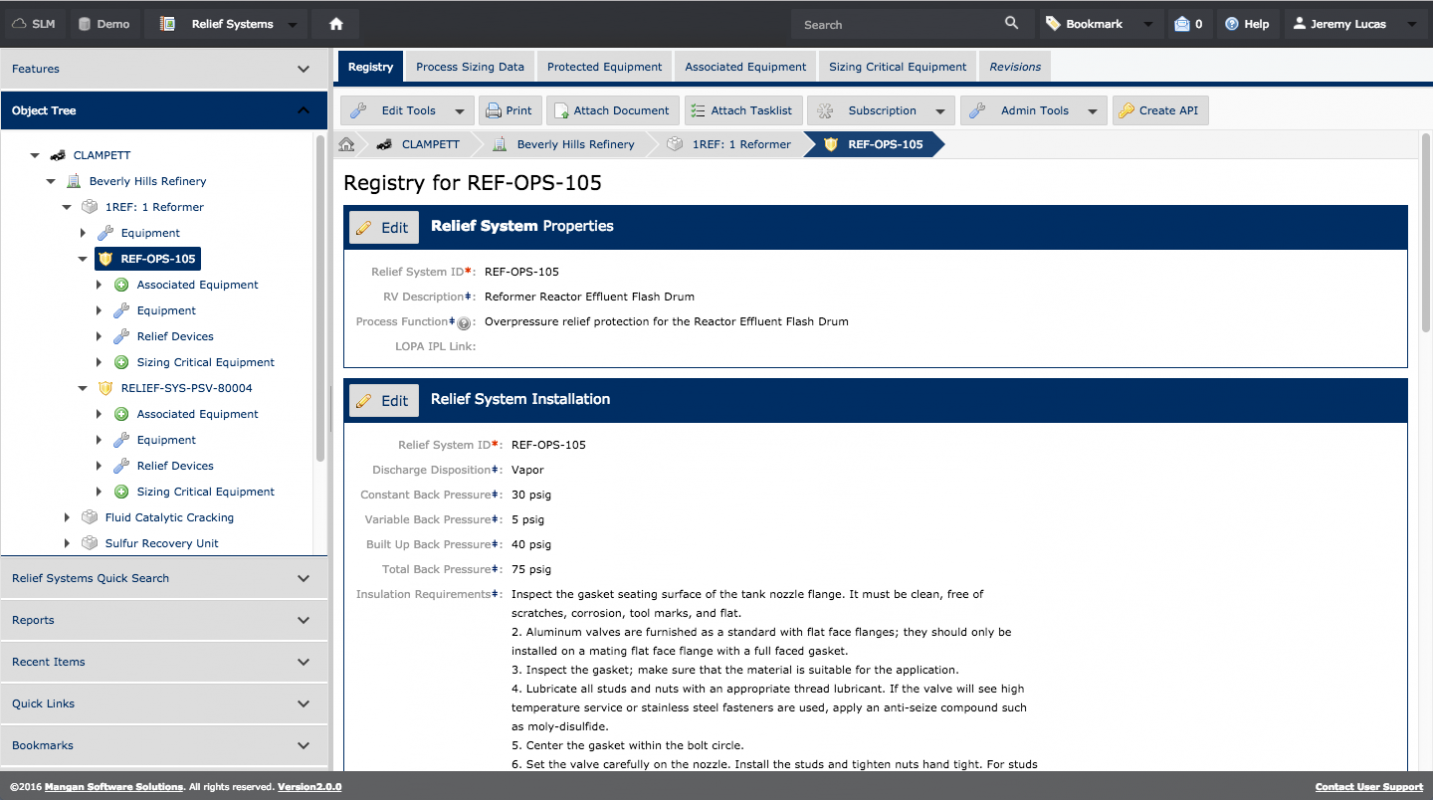

Relief Systems

Click Image to Zoom

- Relief system devices data sheets

- Relief system and equipment registers

- Sync barriers identified in LOPA with relief systems

- Use task lists for relief system engineering checks

- Track associated equipment (block valves and other relief system accessories)

- Relief System test procedure tracking

SLM RELIEF SYSTEM MODULE DATA & REPORTS

The following Data and Reports are part of the SLM V2 core Relief Systems Module.

- Relief System Objects

- Process Sizing Data

- Equipment

- Associated Equipment

- Sizing Critical Equipment

- Block Valve

- Control Valve Limit Stops

- High Integrity Pressure Protective Systems (HIPPS)

- Pipe Spool

- Pump Impeller

- Restriction Orifice Plate

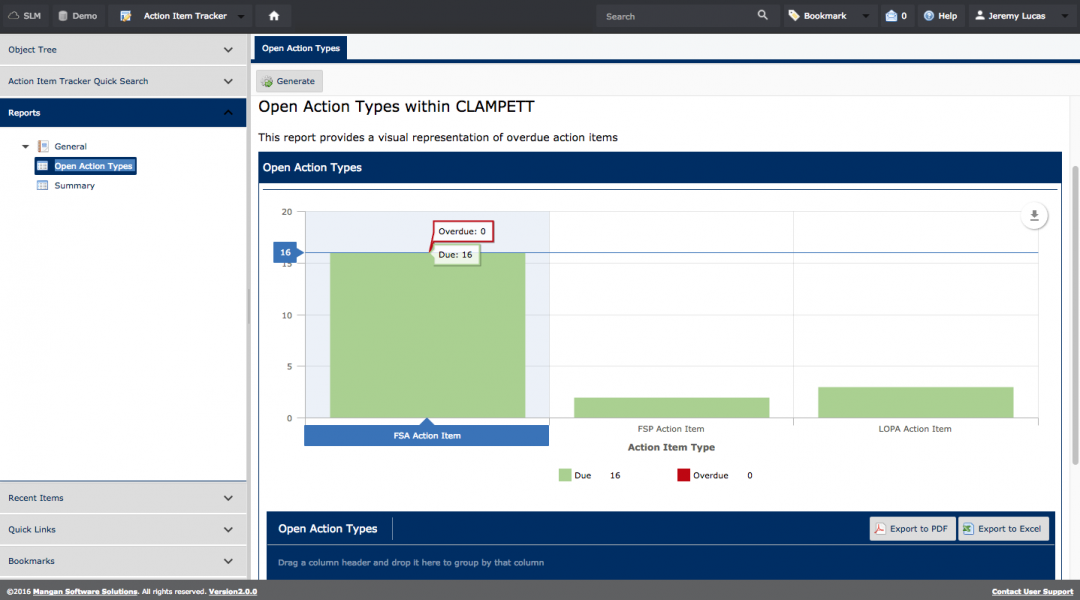

Action Item Tracker

Click Image to Zoom

The Action Item Tracker Module is a centralized location where users can log and access assigned action item information from all modules for follow-up and reporting. Data relating to the action item is linked across modules and readily available for reference purposes.

• Filterable data on enterprise Action Items

• Configurable dashboard and KPI reporting

• Single Source of Knowledge for Action Item Status

• Convenient access to related actions

• Custom fields and configurable Action Item list

• Integration with in-house solutions

• Mobile solutions

• Reporting and file attachments

• Stand Alone Action Items allow for creation of independent action items that utilize the built-in notification system to assign items to system users

SLM V2 ACTION ITEM TRACKER DATA & REPORTS

The following Data and Reports are part of the SLM V2 core Action Item Tracker Module.

Data:

- Action Item Assignment

- Action Item Dashboard

- Personnel Assignment

- Open Action Items

- Closed Action Items

- Action Id

- Date Created

- Category

- Status

- Action

- Reference Contact

- Linked Object Reference

Reports:

- Action Items Assigned

- Open Action Types

- Action Item Summary

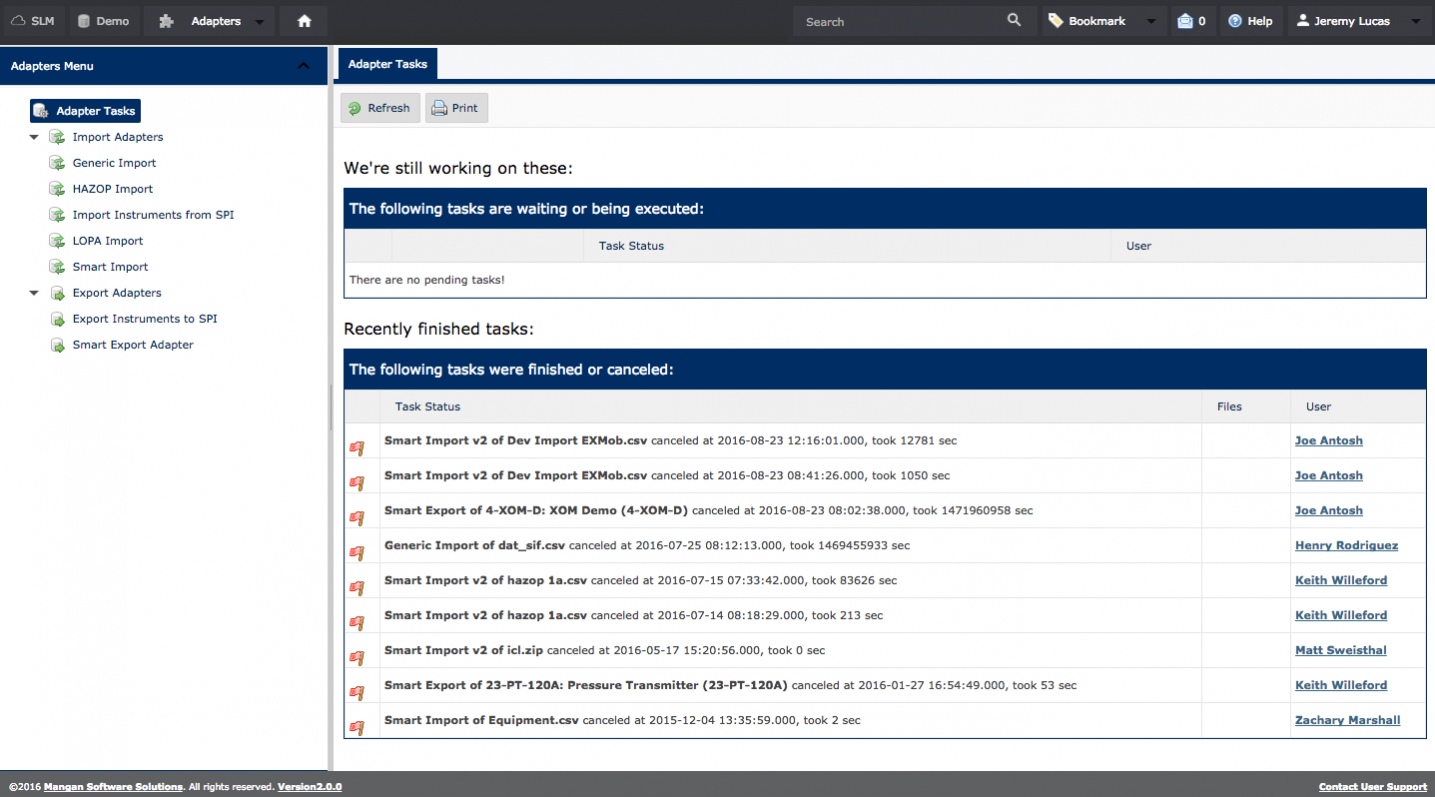

IMPORT ADAPTERS

SLM Import Adapters let you define and store Import Templates for standard csv data import files. Adapters are also available for common data import formats, as well as a data mapping tool to allow users to map data fields to object fields from an import file.

- (New) LOPA Object importer allows for importing the default PHA-Pro LOPA database format and fields.

- (Enhancement) Detailed Instructions on how to use the Import Adapters and the Smart Export Adapter.

- (Enhancement) Improvements to import default PHA-Pro HAZOP database. The HAZOP Specialty Importer has been improved to be capable of importing the default PHA-Pro HAZOP Database format.

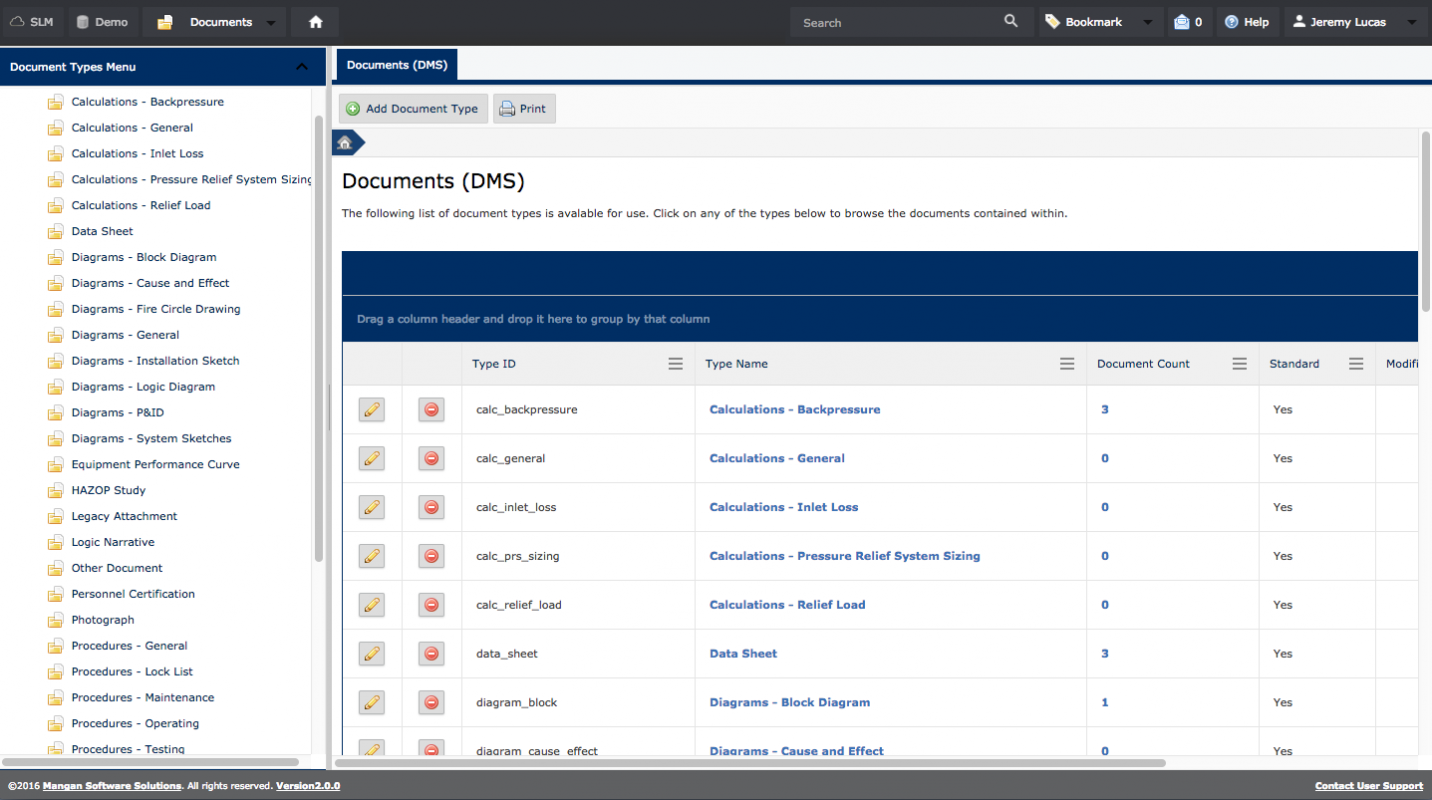

SLM DOCUMENT MANAGEMENT

- Any object in SLM can have documents associated with it

- Specialized Document Logic Models for over 30+ Objects

- Deep Document Search to search contents of PDF documents

- Configurable Document Type Mappings and Rankings

- Remote Document Linking to External DMS Resource URL's

- Tracking of Document Version and External Revisions

Signup for a Demonstration

Sign up for a demonstration of our award winning Safety Lifecycle Management platform.

And See why SLM V2 has redefined safety lifecycle management