Moving Existing Data into the SLM® solution

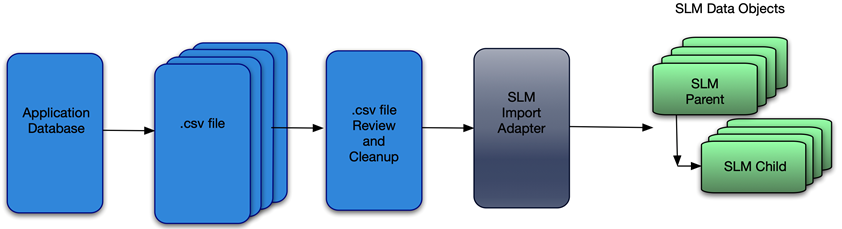

Once the user’s data has been exported to the intermediate .csv file a data quality review and clean up step is advisable. Depending upon the data source, there are likely to be many internal inconsistencies that are much easier to correct prior to import. These may be things as simple as spelling errors, completely wrong data, or even inconsistent data stored in the source application. I recall a colleague noting after a mass import from a legacy database to a Smart Plant Instrument database – “I didn’t realize how many ways there were to incorrectly spell Fisher.”

Once the data has been imported, correcting such things can be very tedious unless you are able to get into the database itself. For most users, errors such as this get corrected one object at a time. However, editing these types of problems out of the .csv file is pretty quick and simple as compared to post import clean up.

To Import the data, the User goes to the Adapter Module and choses the desired Import Adapter and identifies the .csv file that contains the data. The SLM® solution does the rest.

It should also be noted that SLM® software is capable of exporting data too. The User selects data types to export along with the scope (e.g. a Site or Unit). The exported data is in the form of a .csv file. This can be used to import data into a 3rd party application, or to use a data template to import more data.

Rick Stanley has over 40 years’ experience in Process Control Systems and Process Safety Systems with 32 years spent at ARCO and BP in execution of major projects, corporate standards and plant operation and maintenance. Since retiring from BP in 2011, Rick has consulted with Mangan Software Solutions (MSS) on the development and use of MSS’s SLM Safety Lifecycle Management software and has performed numerous Functional Safety Assessments for both existing and new SISs.

Rick has a BS in Chemical Engineering from the University of California, Santa Barbara and is a registered Professional Control Systems Engineer in California and Colorado. Rick has served as a member and chairman of both the API Subcommittee for Pressure Relieving Systems and the API Subcommittee on Instrumentation and Control Systems