Thoughts on Prescriptive Design – It Doesn’t Solve Everything, and Sometimes Doesn’t Solve Anything

Some Organization’s feel they can address the requirements of the Safety Lifecycle by developing prescriptive requirements. This can be effective in enforcing some level of conformance with Safety Lifecycle requirements, but it can also have the opposite affect if not done properly.

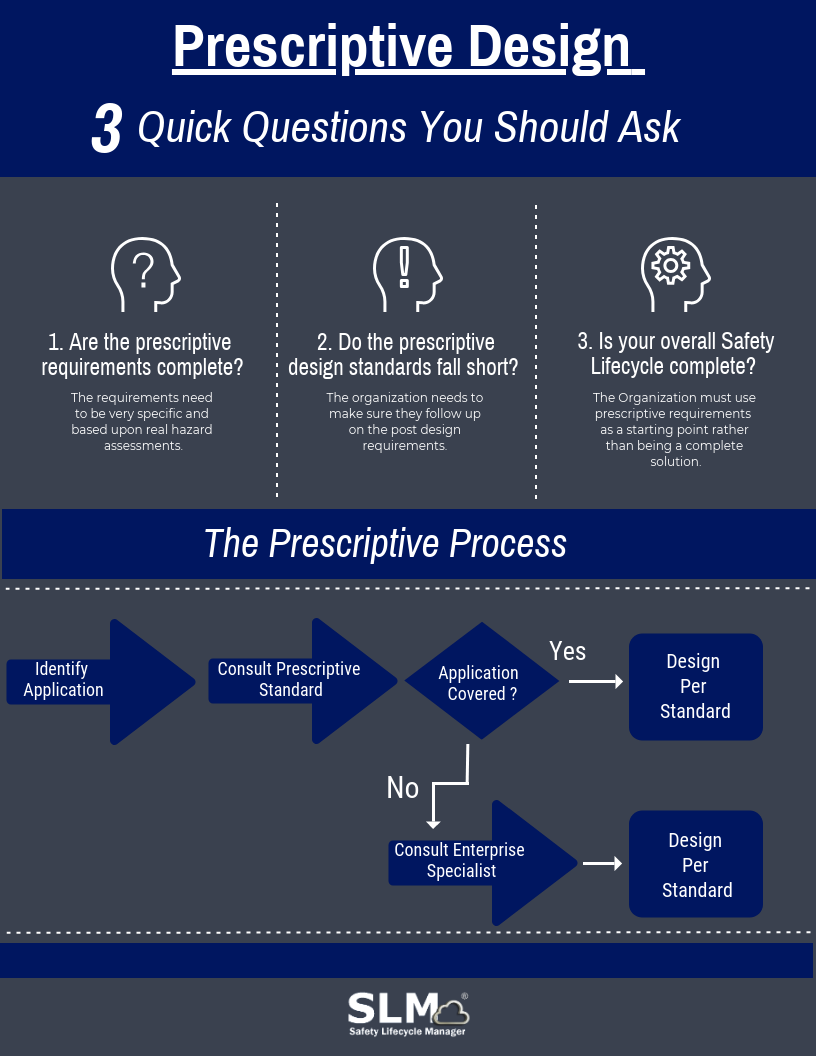

1.) Are the prescriptive requirements complete?

Compliance with the Safety Lifecycle is far more than a company standard simply stating “all fired heaters shall be equipped with a system that shuts down the heater upon unsafe conditions”. That is not very useful. The requirements need to be very specific and based upon real hazard assessments. For a prescriptive design program to be effective, the required designs need to address:

- Anything that constitutes a robust design including identifying specific requirements such as specific required Safety Instrumented Functions (SIF) (e.g. heater fuel gas is shut off when the fuel gas pressure is less than the value required for minimum stable firing)

- Details such as voting inputs and outputs, physical configuration, component selection, testing, etc.

- A complete detailed Safety Requirements Specification (SRS)

Additionally, when a Safety Instrumented System (SIS) is designed based upon the prescriptive requirements, it still needs is own application specific SRS. An SRS in a standard can be a good starting point, however it still needs to be adapted to a Site’s practices

2.) Do the prescriptive design standards fall short?

Ownership requirements typically do not address Site organizations and procedures. However, they need to be addressed in order to assure that post design Safety Lifecycle functions (such as testing, performance reporting, performance reviews, training, etc.) are performed. If an organization has good prescriptive design standards they also have to make sure they follow up on the post design requirements.

3.) Is your overall Safety Lifecycle really complete?

Prescriptive design standards that don’t focus on the overall Safety Lifecycle requirements are often perceived by a Site as the end of the requirements. It’s very easy to get into a “we did what they told us to” culture instead of one that understands the entire Safety Lifecycle and makes it a part of their day to day best practices.

If an Organization chooses to use prescriptive requirements it cannot be thought of as being a complete solution. It’s only a small part of the overall requirements. It may be a starting point, but there is a lot more consider.

The Next Step – Operations:

Make sure all prescriptive design standards are accompanied with very specific Safety Lifecycle requirements for the Operation phase of the Lifecycle. This includes requirements for meeting all of the other specific requirements as well as identification of who is responsible for what tasks and how they should report data. This can be difficult because every Site will want to do things their way unless they are provided lots of incentive. Without some level of enforcement, it’s far too easy for the Operations phase to fall apart with missed or incomplete testing, bypassed systems, poor or no data retention or reporting and no continuous process of reviewing performance and making the necessary improvements.

Learn more about the different roles and responsibilities in the safety Lifecycle.

Rick has a BS in Chemical Engineering from the University of California, Santa Barbara and is a registered Professional Control Systems Engineer in California and Colorado. Rick has served as a member and chairman of both the API Subcommittee for Pressure Relieving Systems and the API Subcommittee on Instrumentation and Control Systems.