Benefits of Effective Bypass Management

SA-TR84.01.00 and IEC 61511 ed 2, Part 1, contain extensive discussions of the design and operating procedures for Safety Instrumented Function (SIF) bypasses. Clause 16.2 describes operational requirements such as:

- Performing a hazard analysis prior to initiating a bypass

- Having operational procedures in place for when a protective function has been bypassed

- Logging of all bypasses

In addition to the need of managing process hazards while a protective function has been bypassed, the time a protective function is in bypass affects the in-service performance of the SIF. While bypassed, the protective function is unavailable, so every hour of bypass time increases the Probability of Failure upon Demand (PFD) of the function.

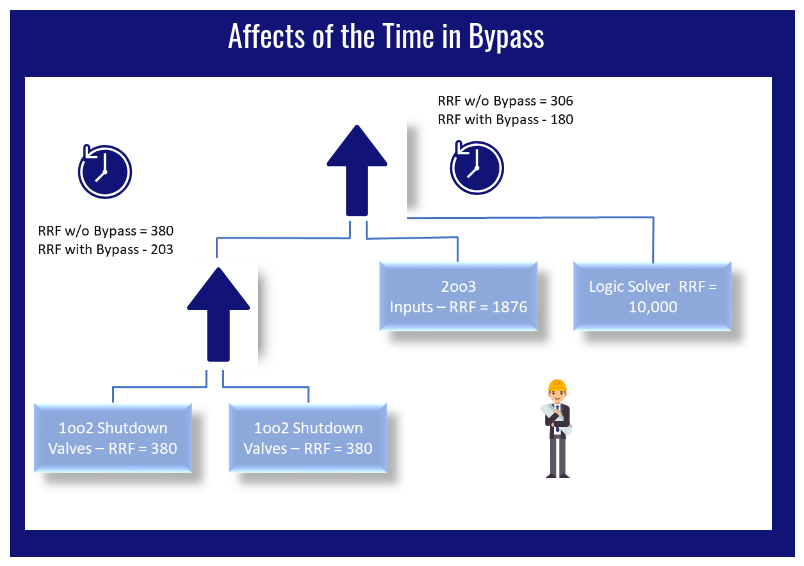

The fault tree excerpt below illustrates how bypassing of a SIF’s shutdown valves for 20 hours in a year can significantly affect the PFD. Without any bypasses, the Risk Reduction Factor (1/PFD) of the SIF is 306. The 20 hours of bypass reduces the in-service risk reduction factor (RRF) to 180, or about a 40% reduction in performance.

The Why:

- Compliance – The Standards governing the Safety Lifecycle require that bypasses be tracked and define specific information that should associated with each bypass. This is crucial to ensuring overall safety.

- Process Safety Management – Excessive bypassing of protective functions has a substantial impact upon overall process safety. Performance of protective functions can be significantly reduced with even moderate levels of bypass. An effective bypass log will help identify bad actors – most bypasses occur for a reason, and if a function is bypassed frequently, it’s typically for the same repetitive reason.

The Benefits:

- Improves Safety and the overall availability through transparent and effective safeguard stewardship – Key Performance Indicators for effective process safety management for safety functions, ensuring the designed integrity is not compromised.

- Reduces Operational Risk through effective evaluation and mitigation of occurrences where safety critical functions or equipment is bypassed– visibility of risk, tracking active bypasses, performing override risk assessments prior to bypassing.

Rick Stanley has over 40 years’ experience in Process Control Systems and Process Safety Systems with 32 years spent at ARCO and BP in execution of major projects, corporate standards and plant operation and maintenance. Since retiring from BP in 2011, Rick formed his company, Tehama Control Systems Consulting Services, and has consulted with Mangan Software Solutions (MSS) on the development and use of MSS’s SLM Safety Lifecycle Management software.

Rick has a BS in Chemical Engineering from the University of California, Santa Barbara and is a registered Professional Control Systems Engineer in California and Colorado. Rick has served as a member and chairman of both the API Subcommittee for Pressure Relieving Systems and the API Subcommittee on Instrumentation and Control Systems.